Latest

-

Oaks Hyde Park Plaza

Commercial Grade Controller helps Oaks Hyde Park Plaza Manage Outdoor Pool Water Quality

Client: Oaks Hyde Park Plaza

Facility: Hotel Pool and Spa

Equipment: PC5100 Dual ppm programmable controller

GianMarc Binskin, Facilities Manager at the Oaks Hyde Park Plaza required a replacement controller for their facility and approached CHEMTROL via a water treatment company with a view to finding a more reliable unit. This is his experience of the controller, and how it helped him provide accurate water treatment of the rooftop swimming pool, including sanitizer (ppm) ORP, pH, TDS with auto water replacement and water balance.

Tell us about your facility…

Oaks Hyde Park Plaza is a 182-room building in the Sydney CBD with a 60,000 litre rooftop swimming pool, sauna and spa. These facilities are used throughout the year receive a mixture of both high and low volumes of usage. Despite this usage they must always meet the relevant public health regulations for swimming pools used by the patrons.

The rooftop swimming pool at the facility

Did you have a specific problem with your existing setup?

The property had a basic domestic grade controller which only had the ability to measure ORP and pH, and without calibration and constant checks this device was prone to giving incorrect and sporadic readouts. The inconsistent readings meant I had to constantly take manual readings to ensure the water chemistry of the swimming pool was at the required levels.

We needed a controller with all the features suitable for a commercial facility. As you know it is a mandatory requirement prescribed under the Public Health Regulations in NSW that the disinfectant and pH levels be recorded prior to opening and once during the opening period.

How does the CHEMTROL controller help you manage your facility?

It is a fully featured commercial grade controller, so it not only provides dual PPM control but also multiple readings for pH, ORP, TDS as well as temperature monitoring and water balance. The device also records all the data and backs it up, allowing for confidence when inspections occur. These are essential features for our facility which prioritises the comfort, safety and health of its patrons.

Has the new controller changed your workload?

The new controller has cut my workload significantly. Once calibrated the constant monitoring and instant readouts mean that I am able to reduce the number of manual tests required per day from the original 5 of the previous set up. The remote access function also means I can access the data throughout the day or if I am not at the pool. And with the pool being an outdoor facility, I can also monitor the water quality after rain, and the controller will alert me if adjustments to the water chemistry are required.

When our spa comes online in the near future we will also need this facilities water quality monitored. Ultimately, we would love to have our controllers integrated into a Building Management System (BMS), and be able to have the capability for remote operation and monitoring.

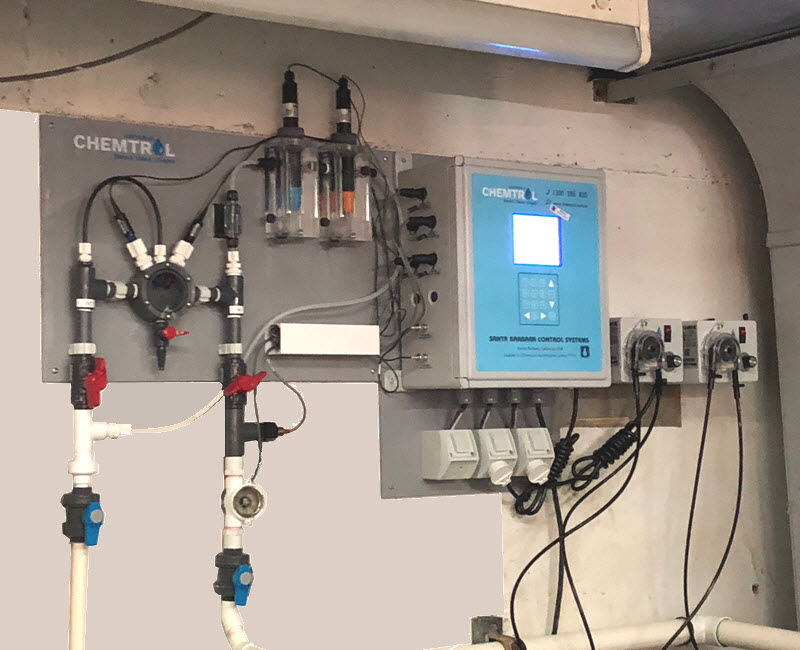

The CHEMTROL® PC5100 Programmable Controller installed at the facility.

CHEMTROL® PC5100 Controller

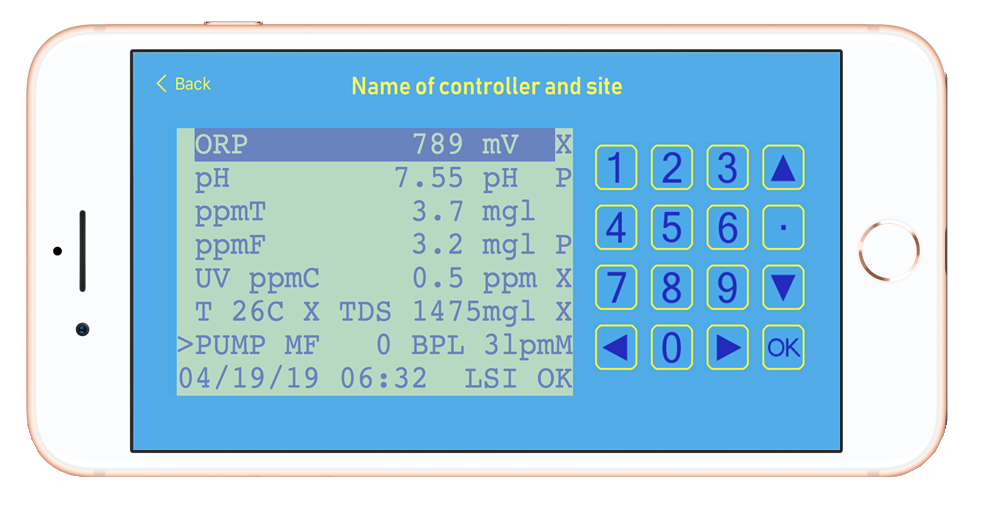

The PC5100 programmable control system includes a complete automatic control of water chemistry. Dual PPM control with UV, pH, ORP, TDS, water balance, water saturation, as well as heating and temperature monitoring. A true duplex remote operation technology with identical duplicate screens on both the controller and the computer. It also has a user-friendly main screen display that enables you to monitor and control all the process functions at a glance and respond to prevailing conditions.

PC5100 Controller display

Get in touch for advice on the best controller for your needs. Our selection chart can help you decide what features you need and which CHEMTROL® controller is right for your application.

Categories

- Yarra Ranges Council, Victoria

- Southern Swim School, Kirrawee NSW

- The new PC1500 range is now available

- Peristaltic metering pumps for pools and spas

- Booster backup for sanitiser + pH

- MidCoast Council and YMCA NSW

- Five-O-Five Apartments

- Future Swim School

- Sustainability: Cooling Towers

- Coughlan’s Swim Centre

- New features and functionality

- CHEMTROL wastewater controller helps ensure regulatory compliance

- URBNSURF Melbourne

- Lineage Logistics expands with CHEMTROL®

- Smart Web Server Upgrade

- PVDF Flow Fitting Products

- Building Control & Management Systems (BCMS)

- The Importance of Corrosion Monitoring

- CHEMTROL® Controllers Are 5G Compatible

- Total Cost of Ownership (TCO)

- North West Brewing Co

- Simplify the Complicated with the A1A Dosing Pump

- Kirby Swim School (WA)

- Dual Boiler Controller With Remote Monitoring Capability

- City of Sydney Aquatic Centres

- Mt. Wilga Private Hospital

- Newington College NSW

- Bradken Steel Foundry VIC

- Panthers Elite Sport Academy

- Sustainability: Swimming Pools and Spas

- Oaks Hyde Park Plaza

- New CT requirements NSW – 2018

- HydroFlow Water

- Cooling towers and Legionella

- Web Server Upgrade

- Emergent Cold