Latest

-

Smart Web Server Upgrade

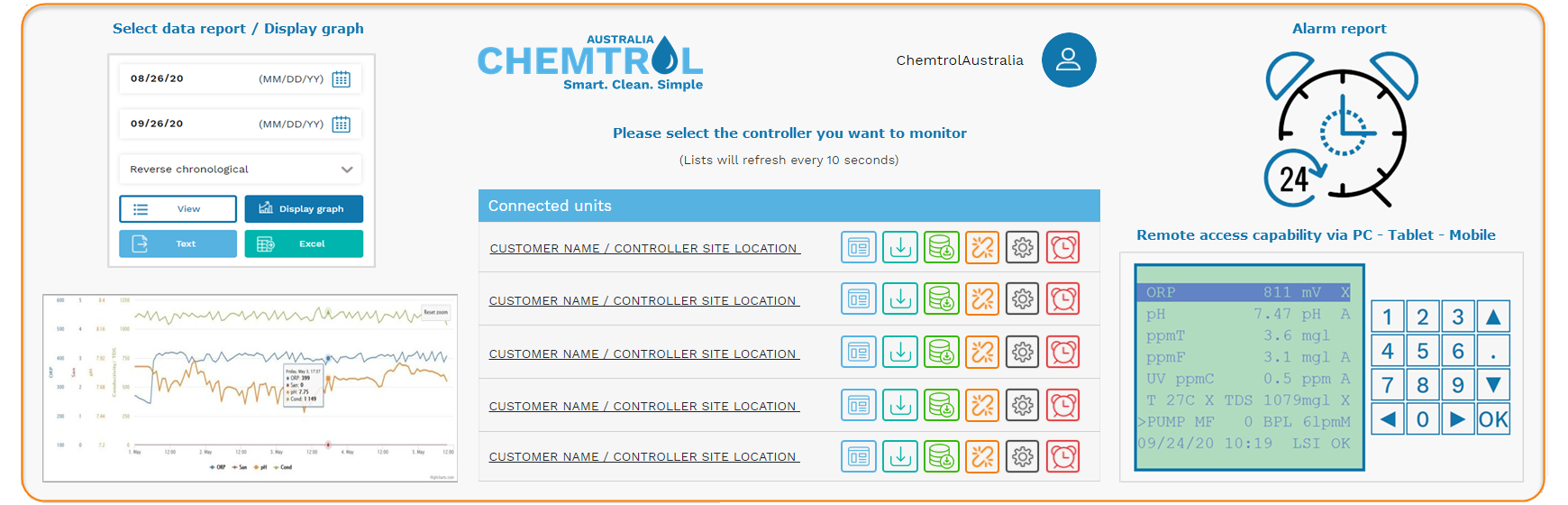

New user-friendly interface, additional features and mobile-friendly

SYDNEY, NSW – 14 Oct 2020

We are committed to continually improving our products, and we wanted to let you know that our Smart Web Server portal has just had a big face lift.

The interface re-design and feature upgrade provides many benefits for you, including:

- A new user-friendly interface with all key data clearly visible.

- Simple colour coded icons and graphs make it easy to make changes and access critical data

- A mobile-friendly view you can access on any device (PC, phone or tablet) from anywhere.

- Automated backups and disaster recovery with all data secure on Amazon AWS Cloud Servers (Australia + USA)

The new version will be rolled out on Oct 14th and will automatically update – so there is nothing for you to do, and all your current data will be retained.

As well as real-time control of all operating functions the Smart Web Server gives you access to:

- Real time status reports

- Trend graphs with combined readings for multiple instruments

- Investigation graph with adjustable intervals and zoom capabilities

- Automatic alerts by email or text message

You can also easily monitor and control any number of controllers from the Smart Web Server.

CHEMTROL® : Next-generation technology today

Our commitment to ongoing research and development, conducted at our laboratory in California ensures our products not only have industry-leading reliability and sustainability benefits – and are constantly integrating next-gen technology – like 5G mobile technology.

Have questions about accessing the new Web Server interface? Call us on 1300 585 820 and we can talk you through the changes.

-

PVDF Flow Fitting Products

TEFEN PVDF fittings: for exceptional chemical resistance, stability and purity

TEFEN PVDF fittings: for exceptional chemical resistance, stability and purity SYDNEY, NSW – 22 Sep 2020

Did you know that CHEMTROL® can supply you with PVDF connectors and flow fitting products for your facility – a high performance plastic.

PVDF – polyvinylidene fluoride – is widely used in high tech applications where exceptional chemical resistance, high purity, stability and high mechanical strength are required. For this reason it is specified in high purity water systems such as water treatment plants – for pipes, valves and connectors. It is also widely used for filtration and housing equipment. It is also valued in applications where failures associated with brittleness, chemical or abrasion resistance are prime concerns.

PVDF – polyvinylidene fluoride – is widely used in high tech applications where exceptional chemical resistance, high purity, stability and high mechanical strength are required. For this reason it is specified in high purity water systems such as water treatment plants – for pipes, valves and connectors. It is also widely used for filtration and housing equipment. It is also valued in applications where failures associated with brittleness, chemical or abrasion resistance are prime concerns.

What is PVDF?

PVDF is a semi-crystalline, superior high purity thermoplastic fluoropolymer with superior increased resistance to elevated temperatures, chemical corrosion, permeation, degradation, nuclear radiation, ultraviolet attack and growth of microorganisms.

PVDF has exceptional chemical resistance combined with good mechanical strength over a good temperature range. Its best attribute is chemical resistance. For this reason PVDF fittings, connectors and pipes provide a number of benefits, including:

Stable in nature

Stable in nature- High working temperature: 145 ºC (subject to application)

- Low melting point: -20 ºC

- High working pressure: up to 14 BAR (200 psi)

- Low permeability to liquids

- Resistant to chemicals

- Non-flammable when exposed to flame

- Lowers total cost of ownership over time

PVDF is also utilised in the pharmaceutical and food processing sector, where the high purity and sanitation capability make it an invaluable surface material.

PVDF in water treatment applications

The TEFEN PVDF fittings are commonly used in water treatment applications, deionization, distillation and demineralization. They are used for their chemical resistance to handle salts / brine solutions, strong and concentrated acids, hot corrosives, aromatics, and halogen solutions such as chlorine and bromine.

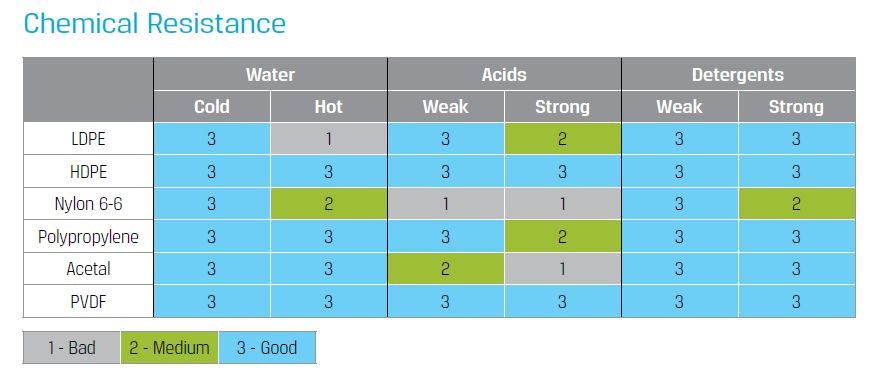

PVDF vs PVC vs metals

When compared to PVC (Polyvinyl chloride) PVDF operates at higher temperatures – 145ºC vs 60ºC. PVDF also has increased mechanical durability to PVC and Chlorinated polyvinyl chloride (CPVC), and is more resistant to permeation and to a greater number of chemicals.

When compared to metal plumbing PVDF is not susceptible to corrosion, rusting or corrosion – and has a higher resistance against chemicals, including chlorine-based compounds such as hydrochloric acid and HCl. In terms of installation and costs PVDF is similar to metal and stainless steel.

Fig. 1 Chemical resistance of PVDF vs other materials.

PVDF Flow Fitting Products

CHEMTROL offers a full range of PVDF flow fitting products that include connectors, nipples, couplings, elbows, caps and more.

Call us on 1300 585 820 for a chat or visit our PVDF flow fitting page to browse our full range

-

Building Control & Management Systems (BCMS)

One-Box Solution Integrates Seamlessly with Building Control & Management Systems (BCMS)

SYDNEY, NSW – 9 Sep 2020

Looking for an integrated one-box solution to seamlessly integrate with your facilities Building Control & Management Systems (BCMS)?

Unlike other vendors who have clumsy add-ons, our programmable water chemistry controllers have all the functionality you need integrated right into the unit, so all communications reside in one compact box. This allows them to interact and ‘talk’ with your Building Control & Management Systems (BCMS), including the following open protocol languages:

Modbus IP – Modbus RTU – BACnet IP – BACnet MSTP – LonWorks

This ensures broad compatibility and interoperability with your BMS, and allows monitoring and control of your equipment, data analysis, alarms and programming to be configured directly via the network.

Real Time Remote Monitoring with CHEMTROL Controllers

With our remote operation function any number of facilities can be controlled and monitored, using direct login via our web server or with our dedicated app. This allows:

- Real-time control of all operating functions including status reports

- True duplex operation with identical duplicate screens on both the controller and the computer.

- Operator training and troubleshooting

- After-hours remote control of your building or facility

- Automatic alerts by email or text messages

This also allows the CHEMTROL support team to run diagnostics and troubleshoot your controller if required. In terms of connecting to your controller, and accessing the data it is enerating, this can be done via:

This also allows the CHEMTROL support team to run diagnostics and troubleshoot your controller if required. In terms of connecting to your controller, and accessing the data it is enerating, this can be done via:- A wired Ethernet cable

- A wireless/WiFi connection

- A shared wireless connection (piggybacking multiple controllers)

- 4G or a next-gen 5G enabled router

Manage a facility and need all your data in one place?

Call us on 1300 585 820 for a chat or visit our web access page for more technical details

Categories

- Yarra Ranges Council, Victoria

- Southern Swim School, Kirrawee NSW

- The new PC1500 range is now available

- Peristaltic metering pumps for pools and spas

- Booster backup for sanitiser + pH

- MidCoast Council and YMCA NSW

- Five-O-Five Apartments

- Future Swim School

- Sustainability: Cooling Towers

- Coughlan’s Swim Centre

- New features and functionality

- CHEMTROL wastewater controller helps ensure regulatory compliance

- URBNSURF Melbourne

- Lineage Logistics expands with CHEMTROL®

- Smart Web Server Upgrade

- PVDF Flow Fitting Products

- Building Control & Management Systems (BCMS)

- The Importance of Corrosion Monitoring

- CHEMTROL® Controllers Are 5G Compatible

- Total Cost of Ownership (TCO)

- North West Brewing Co

- Simplify the Complicated with the A1A Dosing Pump

- Kirby Swim School (WA)

- Dual Boiler Controller With Remote Monitoring Capability

- City of Sydney Aquatic Centres

- Mt. Wilga Private Hospital

- Newington College NSW

- Bradken Steel Foundry VIC

- Panthers Elite Sport Academy

- Sustainability: Swimming Pools and Spas

- Oaks Hyde Park Plaza

- New CT requirements NSW – 2018

- HydroFlow Water

- Cooling towers and Legionella

- Web Server Upgrade

- Emergent Cold