Chemtrol® Introduction

Good day, and thank you for the opportunity to present Chemtrol®, and for your time.

My name is Kobby Green, and I’m the MD and founder of Chemtrol® Australia. Instead of diving right into details about Chemtrol® and our product range (don’t worry, we’ll get to that shortly), I want to start by highlighting our approach to technology and product development.

At Chemtrol®, we prioritize listening to our customers and solving their problems. What sets us apart is our commitment to continually refining and improving our product line. This includes our programmable controller range, dosing equipment, and sensor selection.

For instance, we regularly push out software updates to our controllers with new features – all at no additional cost to you! We believe in providing value and ensuring that our products evolve to meet your needs.

Now, I’m going to walk you through a typical real world, problems pool operators face. Why? Because I know you have a 100 other things you need to focus on – and it’s 2024, so technology should be making your life easier, right?!

Overdosing of chlorine

Imagine arriving at your facility in the morning only to discover that your existing controller failed to stop the feed, resulting in excessively high chlorine levels.

Now you need to treat the water in order to reduce the chlorine level, or even close the pool for 24 hours.

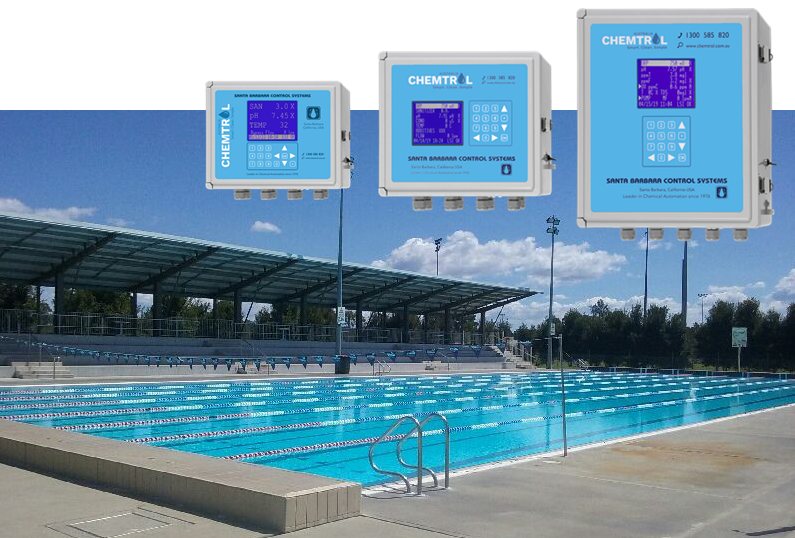

This is not going to happen with Chemtrol. Why? Because they have a critical ‘time limit’ safeguard against overdosing. This safety feature is standard on our commercial pool controllers and it not only prevents overdosing, but it also stops your chemical pumps from running dry for long periods.

It’s just one example, but I wanted to start with something practical that you can easily relate to.

Now, let’s talk about our brand. While we may be relatively new to the Australian market, it’s crucial to understand that we bring over 45 years of experience from the US – the largest and most competitive pool industry in the world.

Chemtrol® Who are we?

High-performance controller manufacturer, specifically designed for commercial pools, aquatic facilities and spas – with critical expertise in water chemistry and automation technology.

As you can see we even put it in our brand name!

√ Control systems manufacturer since 1976, so we have been around nearly half a century, which is around the same time I’ve been around by the way!

√ Made in California USA, which has a $1.4bn swimming pool industry (2023) – so my point here is that our products are tried and tested!

√ Over 100,000 controllers installed worldwide, and they come with a 5 year warranty, which is industry leading in our market!

Chlorine sensors, PPM control

Free available chlorine

– Primary and secondary sanitiser setpoints

– Programmable super chlorination.

Total chlorine

– Combined chlorine display with UV control

Water Chemistry

pH control with a choice of acid, co2 or base feed

– Dedicated output for both co2 & Acid

ORP monitoring for sanitizer reference and oxidizer control backup

TDS level, dump water with auto makeup level control

Temperature monitoring and display

Chemtrol® sensors

To start, our sensors all are covered with 2-year warranty

Total Chlorine – Free Chlorine = Combined level

Solid state PPM sensors feature superior precision and control of chlorine level, with industry leading reliability and low maintenance requirements

pH – ORP – TDS – Temperature

Made in USA, high-performance sensors designed for commercial swimming pools and spas. Normally last for 4-5 years

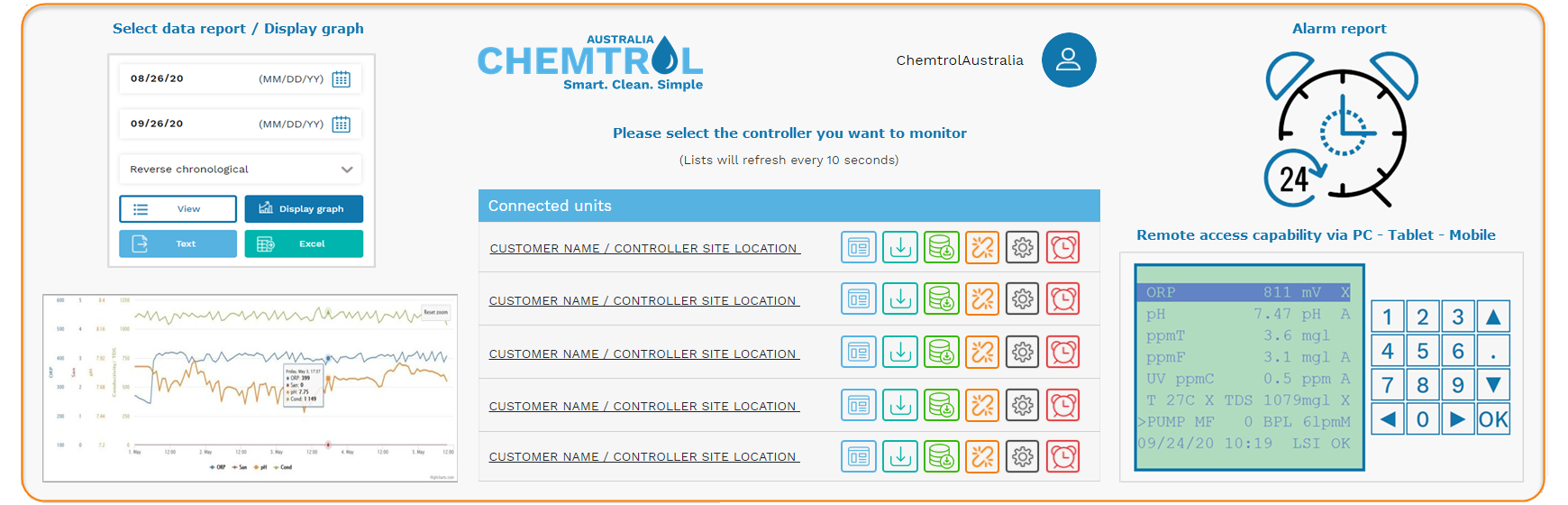

Remote monitoring and control

True duplex operation with identical duplicate screens

With our remote operation function, you can effortlessly control and monitor multiple facilities using your laptop, tablet, or our mobile app.

Unlike others on the market, our remote monitoring management fee is a one-time purchase for the life of the controller. There are no ongoing fees, with the exception of sites with a Telstra sim-card installed.

Our portal

Web Access, Remote Operation

Automatic data logging, a comprehensive history data portal, detailed graphs, and Excel reports are all part of our system.

Plus, receive online alerts directly to your mobile, email, or both.

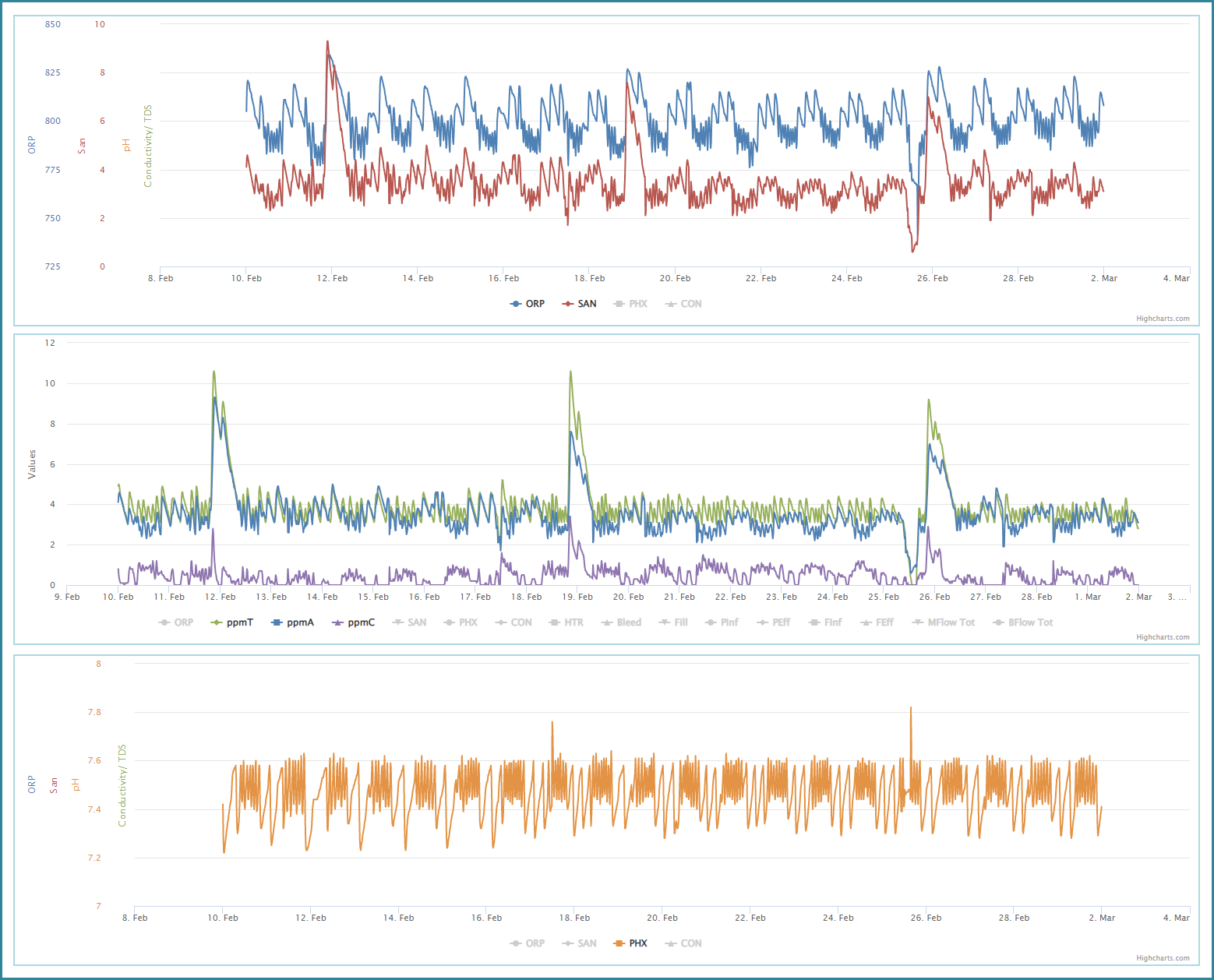

Graphs - Indoor Pool

An example with a weekly shock treatment program

Upper graph – the relationship between Free chlorine and ORP

Middle graph – ppmF, ppmT & ppmC for chloramine monitoring

Bottom graph – pH

CHEMTROL® App

We also offer a convenient app accessible via your tablet or mobile phone

With this app, you have control anytime, anywhere

Imagine standing in front of the controller; the app mirrors the controller screen, allowing you to perform any function seamlessly, with changes reflected instantly on the controller screen.

Total Cost of Ownership (TCO)

Why does the total cost of ownership (TCO) matter to you?

Because the Chemtrol® long-term value package ensures peace of mind, offering:

√ A 5-year electronics warranty on the controller

√ A 2-year warranty on all sensors and other parts

√ Remote operation management fee for the life of the controller

Connect Dosing Equipment to Chemtrol®

If your facility utilizes liquid chlorine and acid, we have the perfect combination recommended for you

Pairing a Chemtrol® unit with a Blue-White® metering pump allows for versatile application

Both liquid chlorine and acid share the same squeeze tube and roller

Essentially, any sanitizer equipment can be directly connected to Chemtrol via 240v, voltage-free, or 12-24vDC, including salt chlorinators generators, calcium hypochlorite systems, brominators, UV systems, and more.

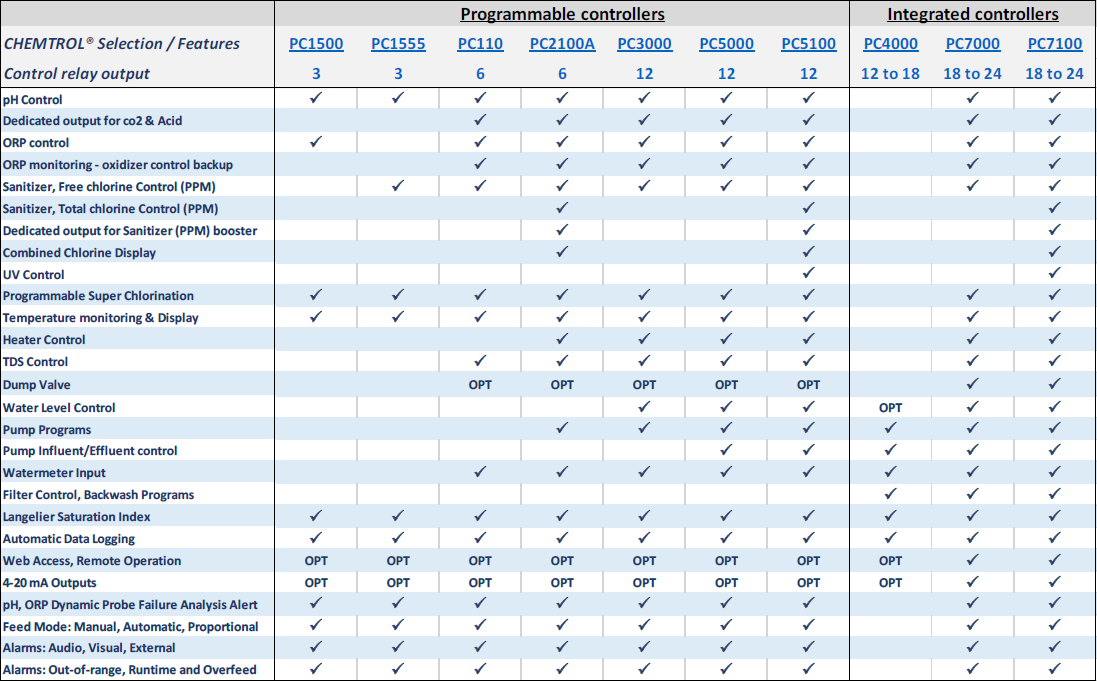

Advanced Pool Automation

√ Main filter pump programs

√ Auto makeup level control with ultrasonic level sensor

√ Water flow-meter Input

√ Heater, temperature control

√ Filter Control, Backwash Programs

Lets review a few important differences: Chemtrol® vs. others

1. Critical Safeguard Against Overdosing: “Time limit”

Designed to automatically disable the feeders or other equipment in the event of equipment failure

A safety feature that any pool controller ‘must have’ in order to prevent overdosing, and chemical pumps from running dry for long periods

2. Dosing pumps cannot lose prime even against maximum line pressure

Cannot vapor lock nor siphoning even when pumping chemicals that off-gas, like Sodium Hypochlorite

3. Software is updated as part of our service

This is our way to help customers with new features and capabilities

4. Unique remote monitoring and control

Identical duplicate screens: from the controller to your PC, Laptop or any mobile device

Remote operation management fee is for the life of the controller

5. Advanced pool automation capabilities

Available only at the Chemtrol® programmable range following 5-year electronics warranty