CT110 COOLING TOWER CONTROLLER

- Product Details

- Specifications

- Installation

- Operation

A Sophisticated Controller

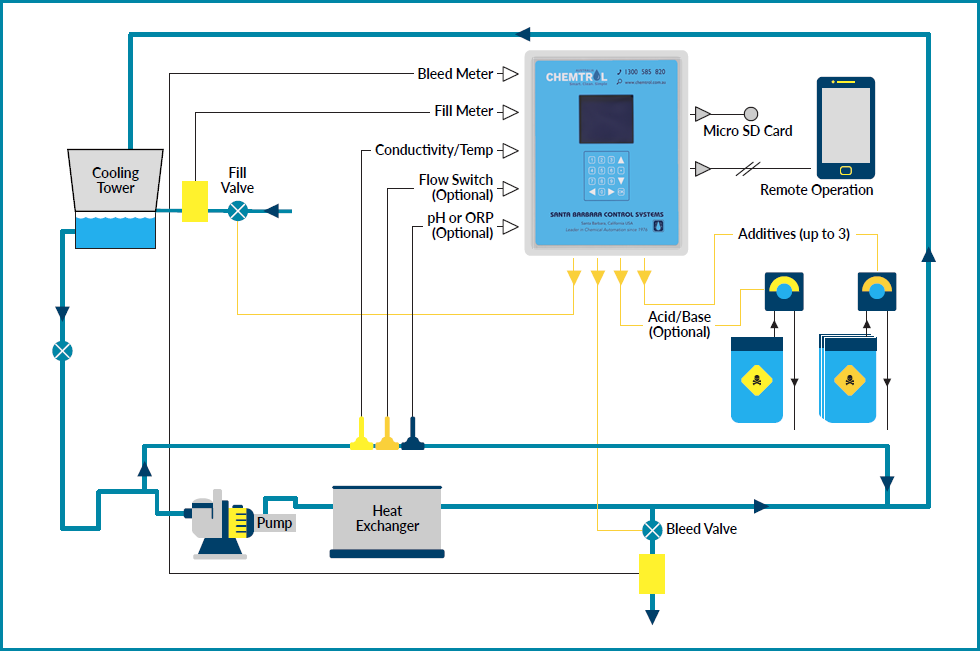

CHEMTROL® CT110 controller is an easy-to-use but sophisticated programmable controller designed for control of conductivity (Total Dissolved Solids) and programmable addition of chemical additives – such as inhibitors, biocides, dispersants, etc. pH control with display of the Langelier Saturation Index (LSI) is recommended as an option. Applications include cooling towers, boilers, and other industrial water applications.

It is easy to install and operate. All menus are displayed on the LCD graphic display screen. Entries are easily made with the 5 keys conveniently located on the front panel. Each unit is supplied with a comprehensive instruction manual with schematics of installation and menu flow charts.

Standard Features

- Large 8-line LCD display,

- Conductivity control with choice of bleed programs,

- pH control option with automatic acid and base feed,

- ORP control option with automatic oxidizer or reducer feed,

- Free Bromine or Total Chlorine (ppm) control option with automatic oxidizer or reducer feed,

- Temperature compensation,

- Dynamic probe testing with sensor failure warning,

- Choice of 1- or 2-point calibration for all sensors,

- Three additive chemical feed programs & chemical alarm level,

- Makeup and bleed water-meter input,

- Langelier saturation index for water balance,

- On-board automatic data logging with adjustable intervals,

- Micro SD card easy data log downloads.

CT110 Specifications

- Large 8-line LCD display for easy monitoring and operation

- Conductivity or TDS control with choice of bleed programs.

- Temperature monitoring.

- Automatic calculation of the Langelier Saturation Index (LSI) for water balance.

- Five separate feed programs for up to three (3) chemical additives such as inhibitors, biocides, dispersants, etc

- Manual

- Cycle Timer

- Auto bleed-and-feed

- Auto bleed-then-feed

- Percent of flow

- Daily schedule

- Two week schedule

- “Booster” chemical feed program to schedule a delayed one-time feed event

- Low chemical level alarm (based on accumulated run time of feed outlet)

- Makeup and bleed water-meter input

- Dynamic probe testing with sensor failure warning.

- Differential signal amplification for added stability.

- Choice of 1, 2 or 3-point calibration for all sensors.

- Automatic data logging.

Options

- CHEMTROL® web-server communication – remote monitoring and control with identical duplicate screens technology. True duplex remote operation via Ethernet cable, WIFI, or 4G/5G router with sim-card data subscription.

- Modbus/BACnet protocol fhttps://chemtrol.com.au/remote-monitoring-control/or Building Management System communication (BMS).

- Integrated corrosion monitoring system

- Integrated Fluorometer technology system

- Chemical tank monitoring with programmable alarm level

CT110 Installation

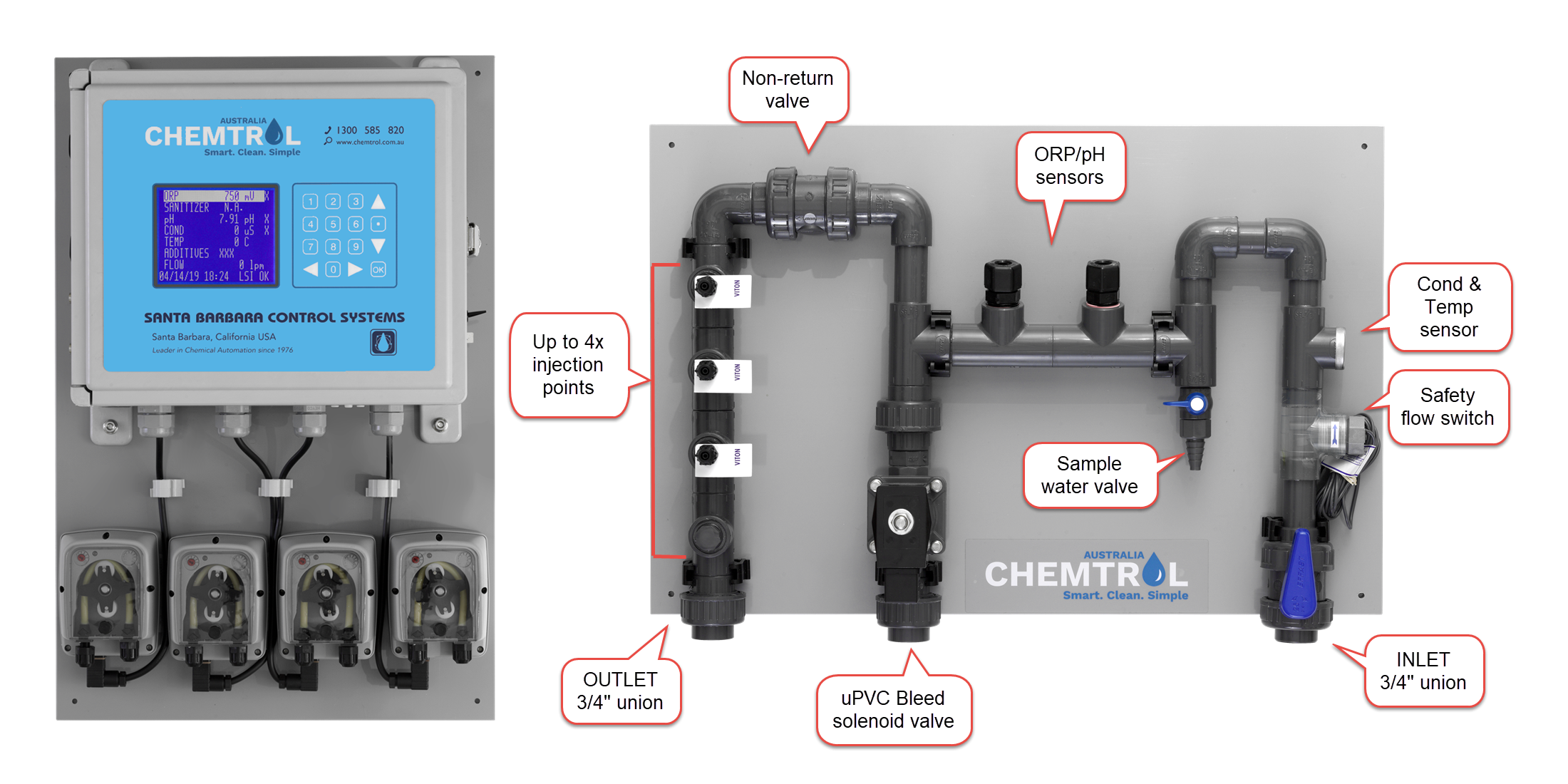

Installation of the CHEMTROL® CT110 controller is quite simple, as shown on the schematics below. To further facilitate installation, every controller comes with a detailed instruction and operation manual.

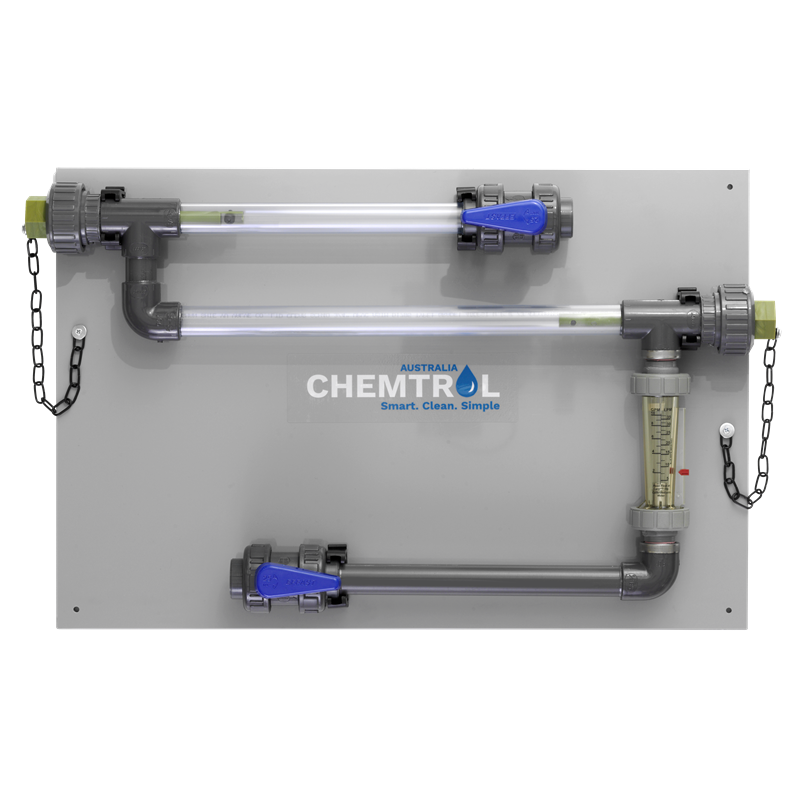

To assure proper water sampling and sensor performance, it is highly recommended to install the CHEMTROL® CT110 with a Bypass line assembly manifold.

CT110 Operation

The CHEMTROL® CT110 controller operates like a computer with an LCD screen display and direct access to all menus and submenus. The front panel keypad is used to move up and down each menu and enter or exit the submenus. All operating functions can be easily modified from the keypad, including sensor calibration, control setpoints, alarm levels and the different feed programs.

Remote Monitoring & Control

Our range of programmable controllers all have remote access capability, so you can control and monitor your facility 24/7.

With the remote operation function any number of facilities can be controlled and monitored from your computer, or via our mobile App. From a computer simply login directly via your browser using our web-server where the controller display is mirrored on your computer.

True duplex operation that allows real-time control and troubleshooting of all operating functions, including status reports, trend graphs and automatic alerts by email or text messages. You can also access and control your controller via our dedicated app, available for Android and Apple devices.

True duplex operation that allows real-time control and troubleshooting of all operating functions, including status reports, trend graphs and automatic alerts by email or text messages. You can also access and control your controller via our dedicated app, available for Android and Apple devices.

In terms of connecting your controller, this can be achieved via a wired Ethernet cable, WIFI signal, or by using a wireless connection with a compatible 4G or 5G router.

Find out more: web-access options.