Commercial & Industrial applications

Potable water, Turbidity ranging from 0 to 10 NTU, with monitoring and control of pH, TDS, and Chlorine (ppm).

Potable water, Turbidity ranging from 0 to 10 NTU, with monitoring and control of pH, TDS, and Chlorine (ppm).- Process water, PH monitoring and control including chlorine levels, up to 200 ppm.

- Cooling Tower control systems.

- Corrosion rate monitoring 24/7 with remote access capability.

- Boilers, Single and Dual Blowdown Control systems.

- Liquid level monitoring to control chemical tanks sites 24/7 with remote access capability.

- Dual ppm control system with UV, chloramine control for commercial pool and spas.

- pH correction, pH correction system, offering the choice of 1, 2, or 3 tanks simultaneously.

pH neutralization system for municipal discharge, ensuring treated water meets government standards and compliance. - Wastewater, Dual pH verification system for municipal discharge, ensuring treated water meets government standards and compliance.

- Wastewater, Turbidity ranging from 0 to 10,000 NTU, with monitoring and control of pH, TDS, and Chlorine (ppm).

Our programmable controllers are fully customizable and can easily accommodate additional components tailored to your specific application needs.

Here are 10 compelling reasons to choose our product range

Waterproof Cabinet

Our controllers come in an industrial-strength waterproof cabinet made from durable, sealed fiberglass, engineered to withstand Australia’s harsh climate.

Benefit: No need for an extra cover to shield your equipment, ensuring longevity for many years.

Remote Monitoring Capability

Our programmable controllers feature built-in internet capability, including an integrated Ethernet socket ready for connection to your existing local network or future networks. An additional router can be added for connection via major Australian ISPs.

Benefit: No need to purchase any additional electronics.

Screen Duplication Web-server Technology

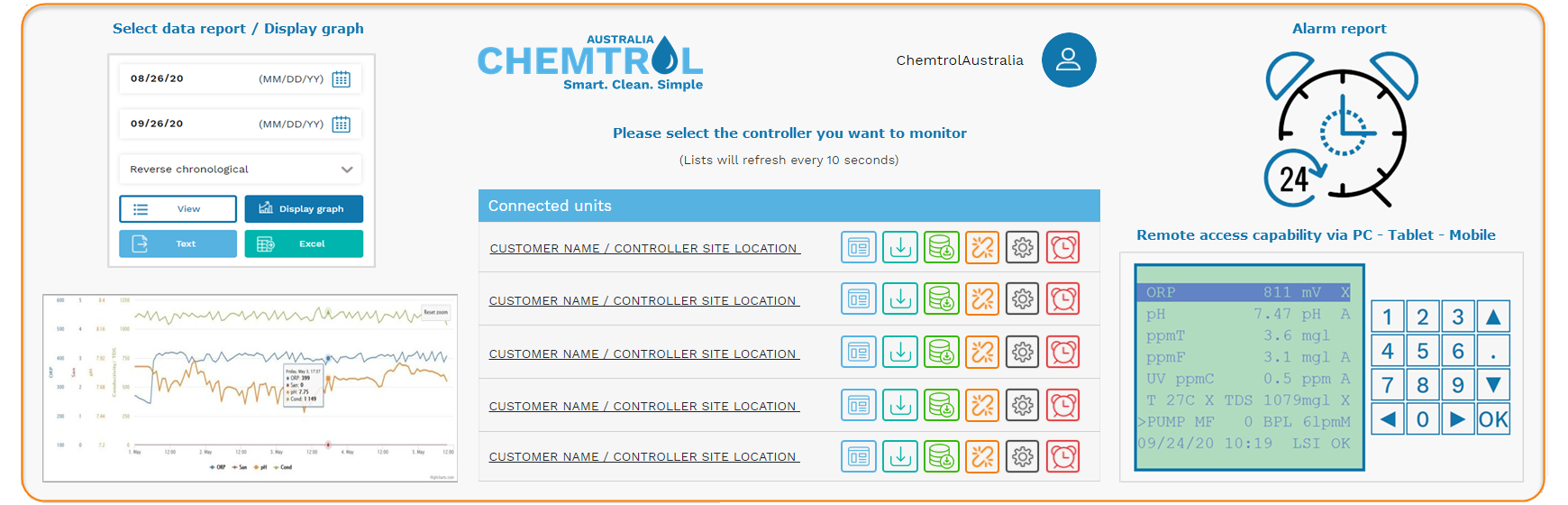

With CHEMTROL web-server capability, you can control and monitor multiple facilities simultaneously from a PC, laptop, tablet, or mobile phone using our unique duplicate screen interface. This ensures that every event or action occurring on the controller is reflected on the remote device’s screen.

Benefit: You can manage and monitor multiple sites seamlessly using the same user-friendly menu mirrored from the controller’s screen, eliminating the need to log in and out for each unit separately.

Control and Monitor with your mobile

CHEMTROL also offers a dedicated app for tablets or mobile devices, compatible with both Android and Apple platforms.

Benefit: Access and view each controller’s menu quickly, and monitor the data conveniently with your mobile app.

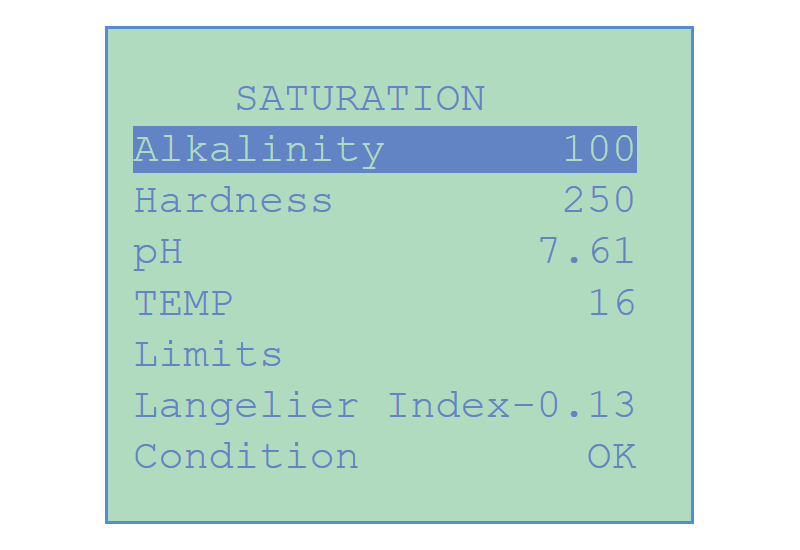

Langelier Saturation Index (LSI)

In addition to the standard probe readings process, our system also incorporates saturation factors such as alkalinity, hardness, pH, and temperature compensation for conductivity and pH measurements, ensuring precise readings. The Langelier saturation index module automatically alerts users to scaling and corrosion conditions.

Benefit: The programmable built-in temperature and Langelier saturation index (LSI) modules enhance water measurement accuracy and provide real-time alerts when water conditions deviate from the desired range.

Proportional Control

In proportional control mode, the controller regulates the feed by turning it on and off within a range of 0% to 100% over a 15-minute time cycle. This mode considers both the dead area, which prevents chatter near the setpoint, and a Progressive Zone control around the setpoint. The width of the progressive zone determines the controller’s return to the setpoint, offering more precise and gradual adjustments.

Benefit: This sophisticated control mode ensures precise regulation, reducing overfeeding, especially in smaller bodies of water.

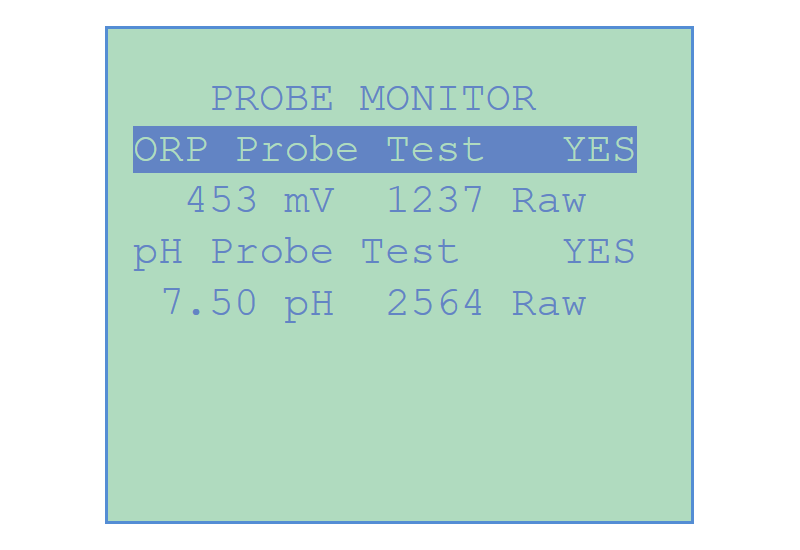

Probe Failure Analysis

Our pH and ORP dynamic Probe Failure Analysis, a proprietary technology (US Patent No. 6,657,546), is a programmable controller feature that ensures dynamic testing of the response of the ORP and pH sensors.

Benefit: This integrated technology allows for immediate detection of probe failure, preventing the development of potentially critical situations.

Accumulative Run-time

For industrial applications, our menu supports various chemical feeding programs, including Automatic, Timer, Percent of Flow, Daily Schedule, and 2-week Schedule. These programs feature options such as time limit, accumulative run-time, and scheduled booster.

Benefit: You have the flexibility to choose the chemical feeding program that best fits your requirements. Additionally, the accumulative run-time function allows you to simulate or project your next chemical shipment.

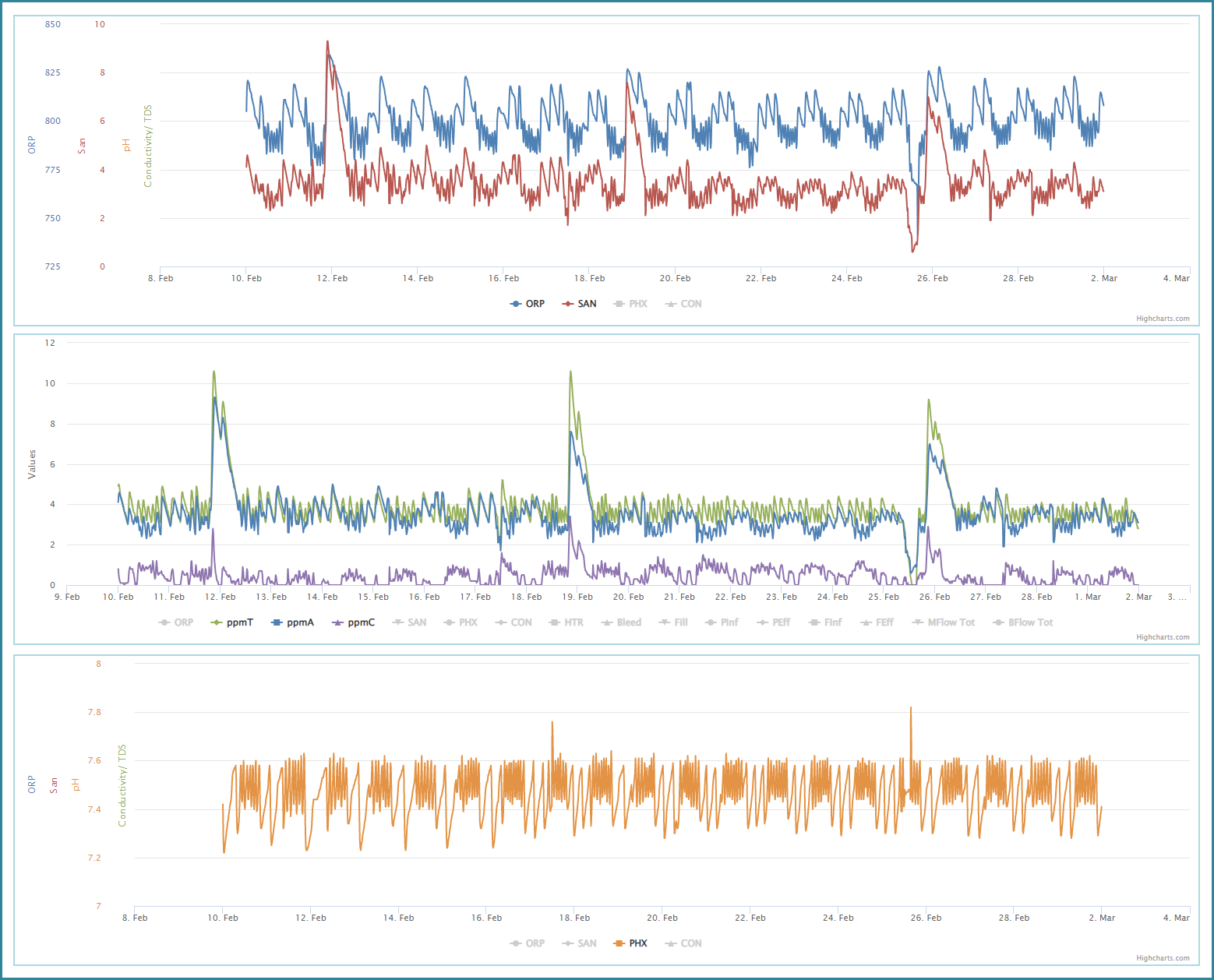

Data Storage and Trend Capability

Our programmable controllers feature integrated data storage and web server sync capability.

Data is continuously written and stored in the controller’s memory device, ready to be synchronized with our web server when you log in.

This data can be easily generated into graphs or downloaded as CSV/Excel data sheets.

Benefit: No need to purchase additional data loggers or memory cards.

Peace of Mind

Your investment is fully protected with a 5-year electronics warranty on the controller and a 2-year warranty on all other parts.

Benefit: Enjoy peace of mind knowing that your instruments are covered within the generous warranty period, minimizing the need for replacements.