Downloadable content

FLEXFLO® A1A Acid and Liquid Chlorine Feeder

- Overview

- Features

- Specifications

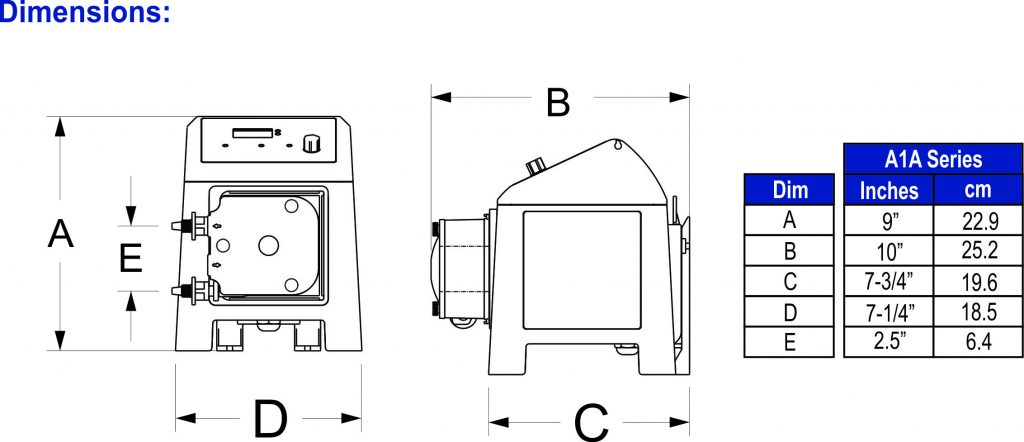

- Dimensions

- Video

- TFD

Specially designed for commercial aquatics and water parks

Max Feed: 100 GPD (.01 – 15.8 LPH)

Max Pressure: 40 PSI (2.76 bar)

For installations requiring higher chemical feed, such as Water Parks and other high-volume Commercial Aquatics for sanitizing (sodium hypochlorite) and pH adjustment (acid) for low maintenance, more trouble-free, and reliable chem feed solution.

For installations requiring higher chemical feed, such as Water Parks and other high-volume Commercial Aquatics for sanitizing (sodium hypochlorite) and pH adjustment (acid) for low maintenance, more trouble-free, and reliable chem feed solution.

- Variable Speed DC Motor

- Rating: NEMA 4X (IP 66)

- Control Methods: Manual, Remote Analog

- 2 Year Warranty

- Patented Tube Failure Detection

- Energy efficient design saves in energy costs

Benefits of a Peristaltic Pump:

- Peristaltic pump design does not have valves that can clog requiring maintenance.

- Self-priming – even against maximum line pressure. By-pass valves are not required.

- Cannot vapor lock or lose prime.

Communication & Interface:

- Remote Start/Stop: Non-powered dry contact closure for remote start/stop.

- One 48VDC @ 80mA relay

- Compatible with Blue-White’s output Flow Verification Sensor (FVS) system.

Superior Engineered Design:

- 2 year warranty

- CNC precision-machined squeeze rollers for optimum squeeze, unparalleled accuracy, and tube life.

- Heavy-duty rotor – single piece plastic rotor means no flexing and increased accuracy with no metal springs or hinges to corrode.

- Energy-efficient variable speed DC motor.

- Specially engineered tubing for long life.

Safety Features:

- Tube Failure Detection (TFD) senses tube rupture preventing hazardous chemical spills.

- Lockout feature to prevent tampering

What’s Included:

- A1A Acid and Liquid Chlorine Feeder

- One tube assembly

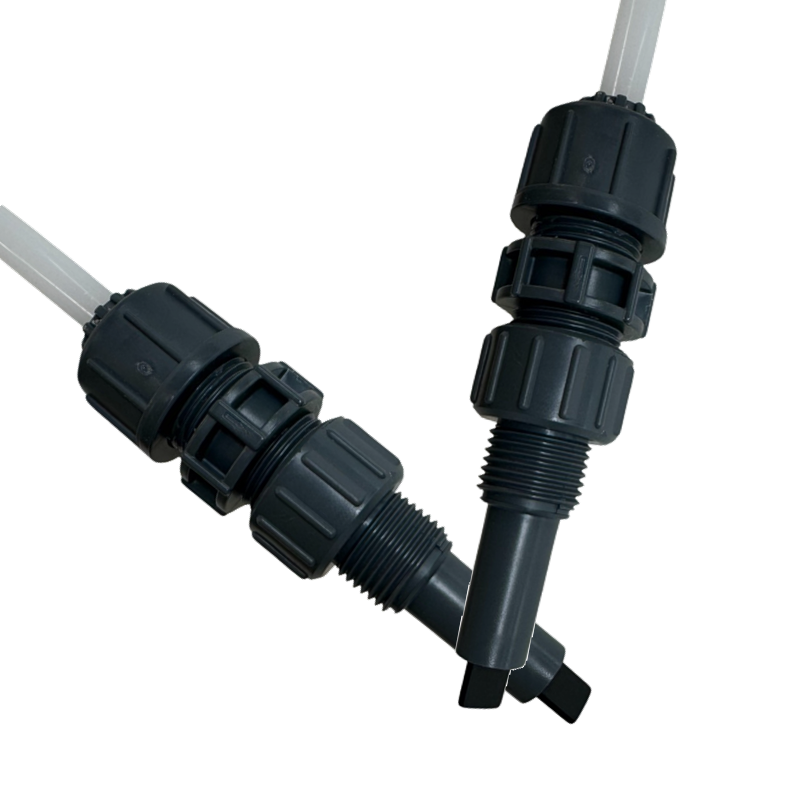

- Suction tube – clear PVC – 5′ length (3/8″ OD, 1/4″ ID)

- Suction strainer

- Suction ceramic weight

- Discharge tube – opaque polyethylene – 5′ length (3/8″ OD, 1/4″ ID)

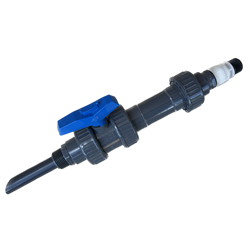

- Discharge injection fitting with check valve

- Mounting hardware kit

- Tube nuts (x2)

Specially designed for commercial aquatics and water parks

Max Feed: 100 GPD (.01 – 15.8 LPH)

Max Pressure: 40 PSI (2.76 bar)

| Maximum Working Pressure (Excluding pump tubes): | 40 psig (2.76 bar) |

| Ambient Operating Temperature: | 14 F to 125 F (-10 C to 52 C) |

| Ambient Storage Temperature: | -40 F to 158 F (-40 C to 70 C) |

| Flow Range Adjustment: | 0.01 – 100 GPD (0.01 – 15.8 LPH) |

| Maximum suction lift: | 30 ft. Water at sea level (14.7 atm psi) |

| Operating Voltage: | 115V60Hz 1 PH (0.6A max.) 220V50Hz 1 PH (0.3A max.) 230V60Hz 1 PH (0.3A max.) 230V50Hz 1 PH (0.3A max.) 240V50Hz 1 PH (0.3A max.) |

| Power Cord: | 240V50Hz = AS 3112 (Australia/New Zealand) |

| Motor: | Brushless DC, 50W. |

| Duty cycle: | Continuous |

| Enclosure: | NEMA 4X (IP66), Valox (PBT) & PA12 |

| Maximum Overall Dimensions: | 18.5 W x 22.9 H x 25.2 D cm |

| Approximate Shipping Dimensions: | 26.7 W x 35 H x 28 D cm |

| Product weight: | 2.7 Kg |

| Approximate shipping wt: | 5.9 Kg |

Tube Failure Detection (TFD) System

Patent No. 7,001,153 and 7,284,964

No False Triggering!

Breakthrough technology for Peristaltic Pumps.

The TFD system will detect a wide range of chemicals (i.e. chlorine, acids, soaps, etc.). This unique technology was designed NOT to false trigger by condensation and washdown. Many companies require the TFD system for their peristaltic pumps.