Sustainability for Swimming Pools

Sustainability for energy and resource efficient swimming pools, aquatic centres and water features

There is a growing focus on sustainability across all sectors, with facilities looking for ways to reduce their environmental impact, conserve energy and cut costs.

The commercial swimming pool sector is a major consumer of energy, water and chemicals – making sustainability a priority from a financial and environmental perspective. According to the NSW Office of Environment and Heritage (OEH) in aquatic centres, energy and water consumption account for up to 90% of operating costs. This has prompted initiatives like the Master Pool Builders Association Australia (MPBAA) Water Neutral Pool, which has a goal of maintaining the volume of water in the pool by minimising water loss and reducing energy and chemical use.

“Chemtrol has integrated sustainability into all aspects of product development, including our programmable controller range, dosing equipment and probes/sensors. Read on to learn how our product range has sustainability built into it”

Precise metering and monitoring essential

Precise metering and monitoring are essential to optimise equipment operation, detect inefficiencies, and support sustainability goals. Ultimately a poorly maintained pool will require more frequent top ups, chemical dosing and backwashing. So the best way to conserve water is to maintain the right chemical balance and ensure your filtration is adequate.

Adopting water and energy performance indicators allows centres to track consumption, efficiency, and make informed, data-driven decisions. By monitoring these resources, aquatic centres can achieve significant cost savings, environmental benefits, and improve their overall efficiency.

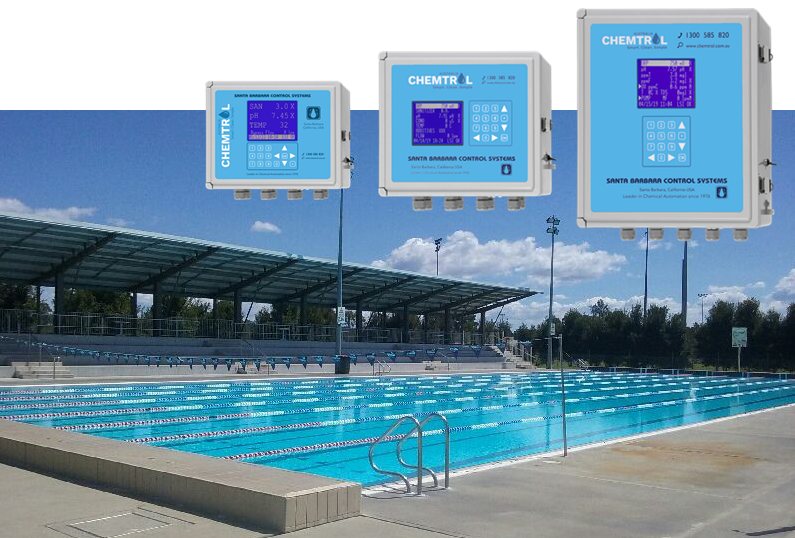

Chemtrol for sustainability and cost benefits

Our ongoing research and development ensures our programmable controllers not only have industry-leading features and reliability, but also have energy-saving features integrated.

This means you get the most energy efficient, low-cost outcome for your facility, including:

- Water savings

- Energy savings

- Longer equipment life

- Reduced maintenance costs over time

All these sustainability features are accessible with our integrated remote monitoring capability – allowing you to monitor and adjust settings via a mobile, tablet or PC.

Let’s take a closer look at all the sustainability features our controllers have, and how they can help you.

Key sustainability features of Chemtrol programmable controllers

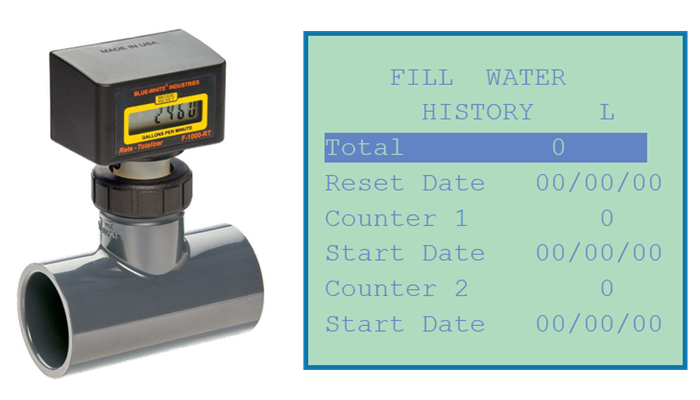

1. Water meter input for consumption monitoring

Water is a finite resource, which means measuring the consumption of your facility – swimming pool, water feature, splash park etc – is critical. Our water meter & controllers can produce consumption data which can be used to identify problems and inform your border water conservation and management plan. You can then analyse and base operational decisions based on specific timeframes – hourly, daily, weekly, month, annual.

This level of monitoring – using time/date data – enables you to detect water leaks and reduce chemical use caused by excessive water consumption. Ultimately you want to reduce the amount you top up, and the number of times you do it, which can result in significant water savings.

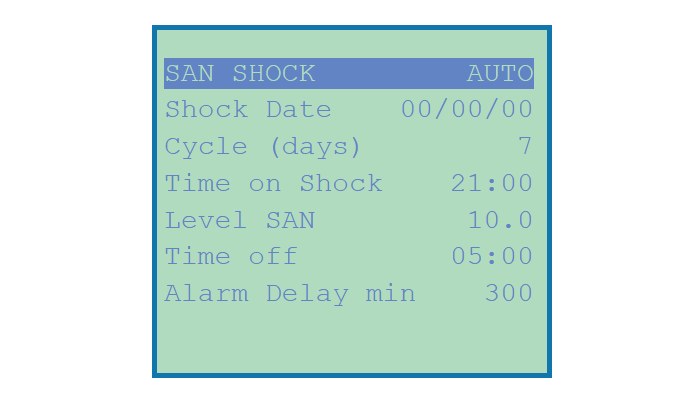

2. Automated, programmable super chlorination

The automated programmable super chlorination feature enhances the efficiency and precision of pool water treatment and promotes sustainability by:

- Reducing chemical usage

- Conserving energy and water use

- Extending the life of your pool surface and pool equipment

Automated super chlorination also reduces the amount of work for staff, so no more manual dosing, which is inaccurate and wastes valuable time. This can be done automatically over the weekend or when the facility is not being used. Automated super chlorination also ensures that your facility’s water quality meets the relevant public health legislation and safety standards. By preventing algae growth and controlling contaminants effectively, the pool water requires less maintenance, resulting in reduced chemical and energy usage – for a more sustainable pool operation.

The Chemtrol programmable controller range also includes the Langelier Saturation Index (LSI), which constantly monitors the water balance and alerts you if scaling or corrosion develops. A pool with corrosive water can cause damage to metals including stainless steel rails, pipes and UV disinfection systems. It can also attack the grout and concrete, and cause the tiles to fall off. The LSI feature helps to extend the lifespan of your pool equipment, including filters and pumps. This also reduces the need for frequent repairs or replacement and contributes to the overall long-term sustainability of your facility.

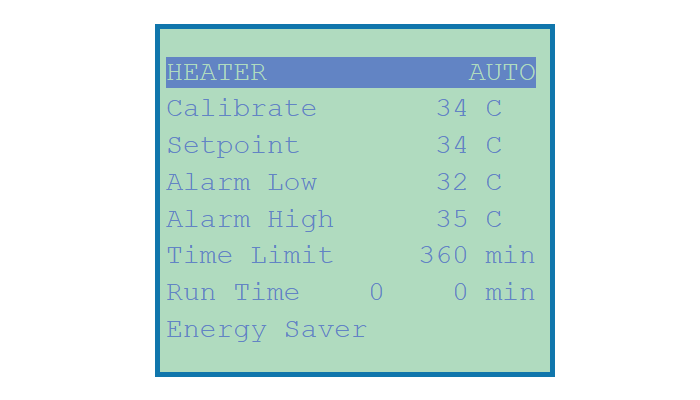

3. Energy savings with heating control

Chemtrol programmable controllers incorporate automatic control of water temperature with a seven-day heater control and energy saver program. The energy saver program is designed to save heating costs when the pool is not being used, such as at night or on weekends. Individual ON and OFF times can be set for every day of the week, with an adjustable low temperature setting.

This feature enables you to schedule heater running times around off-peak periods, and you can also pre-heat during off-peak periods and reduce running during peak periods to save energy. This can result in substantial savings on heating costs. In addition there is no need to purchase a costly new temperature control system just for this feature.

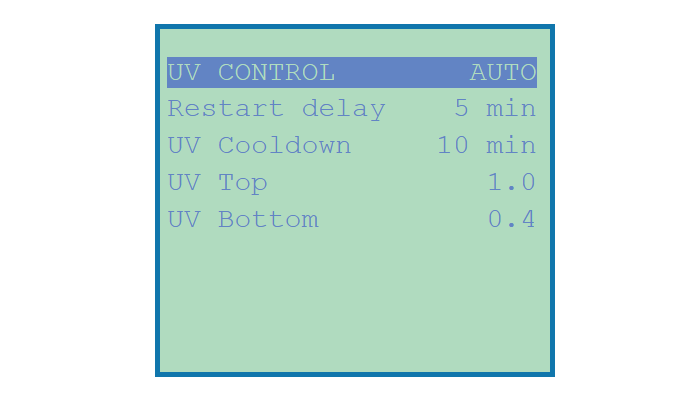

4. Reducing UV sanitation run time

UV systems are an effective way of disinfecting and sanitising pool water, and also require fewer chemicals and less maintenance. Unfortunately they do have a downside: they draw a lot of power when they are operating, which can run up your facility’s electricity bill – especially if they are constantly in use. The reality is that UV systems only need to operate when Combined Chlorine levels exceed +1.0 ppm.

Our programmable controllers for pools and spas – specifically the PC5100 – take advantage of this by only activating the UV system when a defined value is exceeded, for significant energy savings. When measurements are between 0.4 ppm – 1.0 ppm, the controller ensures the UV unit is idle and does not draw any power. With UVs that have 4-20mA we can increase and decrease the amount of UV power in order to optimise power consumption. You have the ability to set the required Combined Chlorine levels and program the controller accordingly.

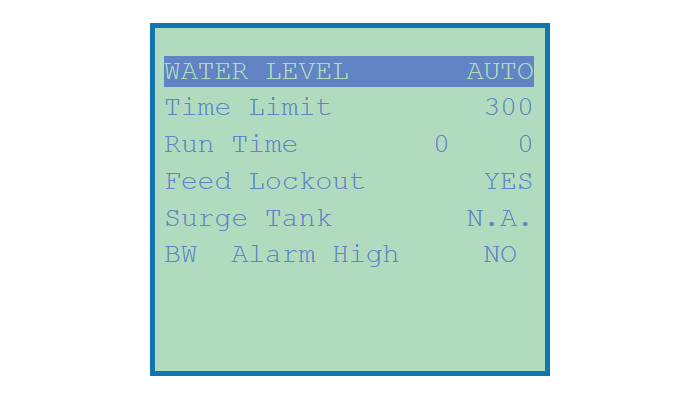

5. Water makeup level control

Automated water level control not only prevents human error but also saves valuable operating time. The precaution time limit function integrated into our programmable controller prevents overfilling and send alerts immediately if the water fill cycle has failed. This can help save on water consumption and reduce your facilities overall water bill.

The water meter feature we covered earlier also helps you monitor your overall water consumption. This is another integrated feature which means you don’t have to purchase a costly new water level control separately.

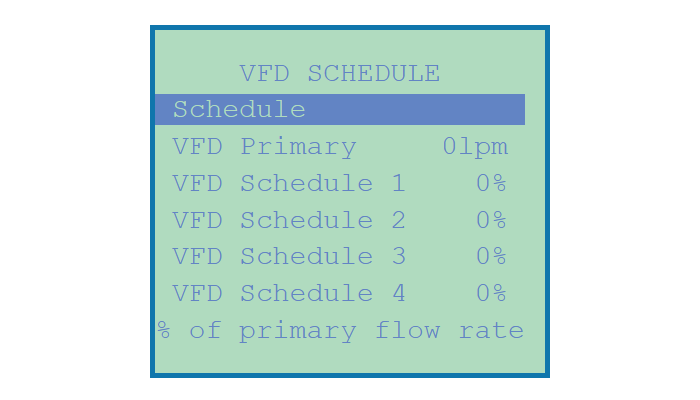

6. Variable-speed pump program

Chemtrol programmable controller’s variable speed pump program can realise further savings on electricity, and help make your facility more sustainable.

A variable-speed pump optimises energy usage by adjusting the motor speed and flow rate to match the pool’s requirements, resulting in reduced energy consumption, lower operating costs, and a more eco-friendly pool system. The ability to control the pump by time/date can also be beneficial for winterising seasonal pools. This includes running the pumps for a pre-programmed period every day during winter.

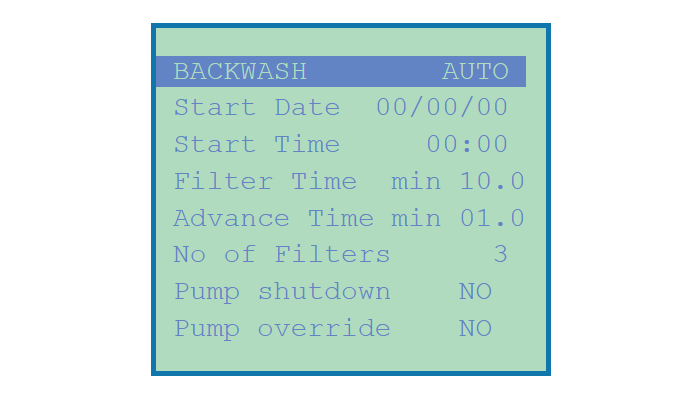

7. Filter control and auto backwash function

A poorly maintained pool is going to put pressure on your filter and require more frequent backwashing. Backwashing is wasteful if done too often or for too long. So the best way to conserve water is to maintain the right chemical balance and ensure your filtration is adequate.

Select controllers feature automated backwash of single or multiple filters using different programs based on fixed schedules or on pressure differential criteria. Complete automation of filter control is preferable to doing this manually (because humans forget or make a mistake!). This can be programmed to happen during the night or over weekends which also saves operator time and effort.