Cooling Tower Installation

SIMPLE Installation

In our commitment to simplify the installation process of CHEMTROL® controllers, we have streamlined everything onto a customized assembly manifold, prepared for easy connection.

This approach ensures proper water sampling around the sensors, facilitating a hassle-free installation that minimizes the integration work required to get your water treatment system operational.

For architects and engineers preparing bids, listed below are various installation options to accommodate diverse requirements.

Bypass line assembly (BPL), Programmable controller range

A choice of 4 models available

The CHEMTROL® cooling tower setup comprises two grey PVC backboards, featuring the CHEMTROL® model CT110— a 6-relay output control system accommodating up to five wired dosing pumps. The customized assembly manifold, equipped with grey uPVC fittings, is ready for seamless connection.

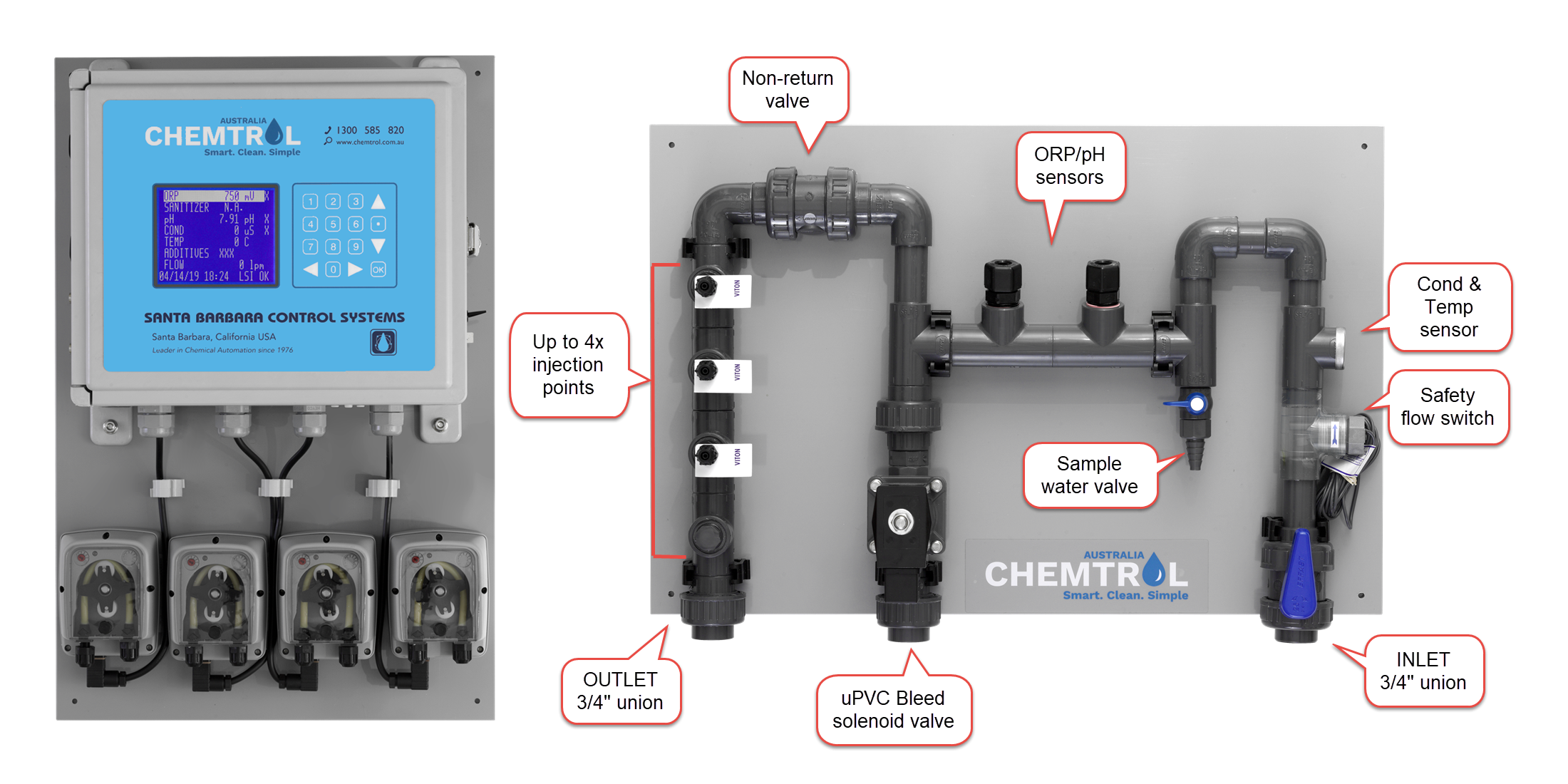

MODEL A

CT110/PC110x Programmable controller

Conductivity/TDS with ORP and/or pH control

– Backboard 600 x 400 mm PVC sheet.

– Up to 4 injection points of programmable chemical additives – such as inhibitors, biocides, dispersants, etc.

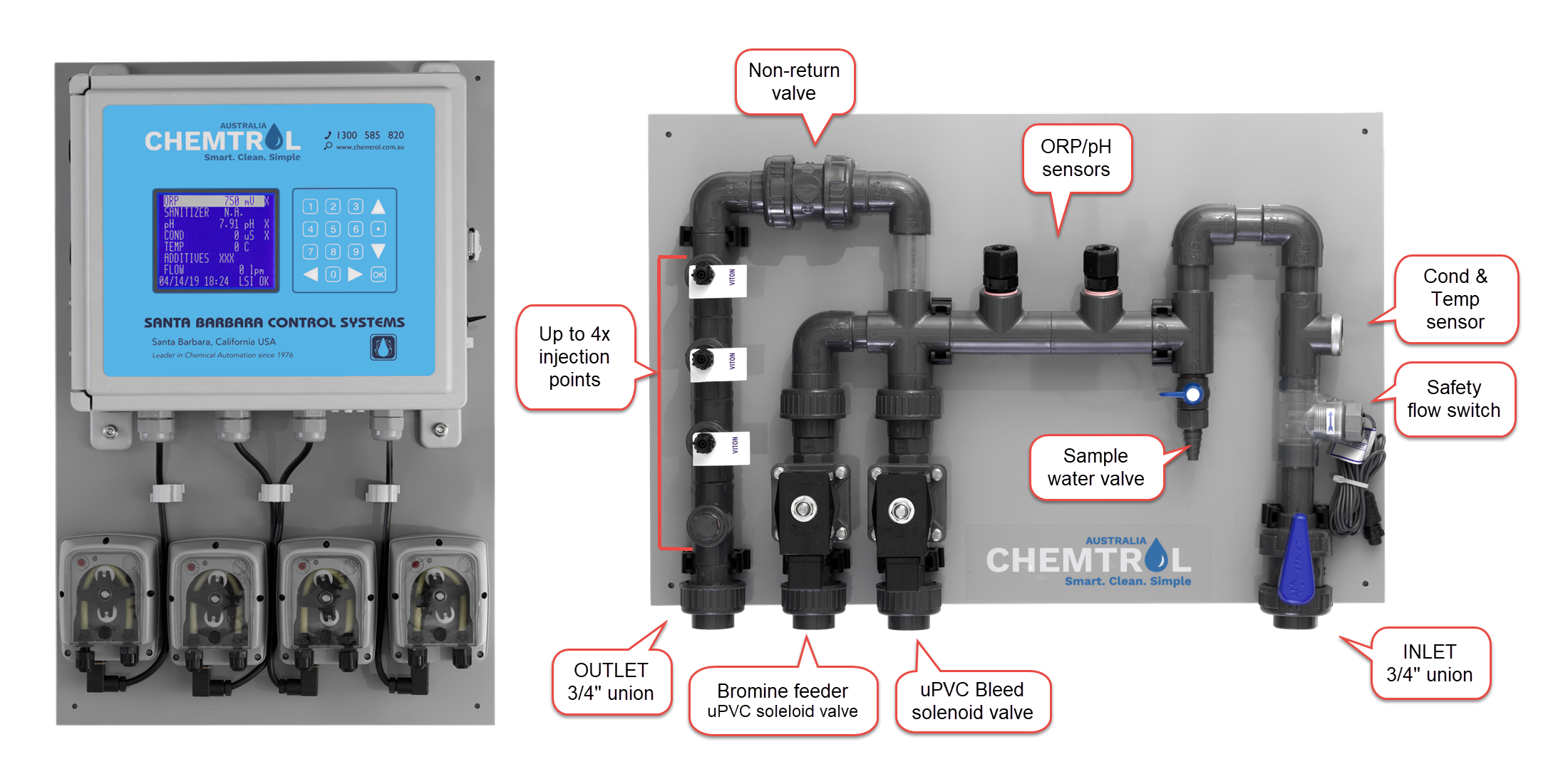

MODEL B

CT110/PC110x Programmable controller

Conductivity/TDS with ORP and/or pH control

– Backboard 600 x 400 mm PVC sheet.

– Extra solenoid valve for Bromine Feeder.

– Up to 4 injection points of programmable chemical additives – such as inhibitors, biocides, dspersants, etc.

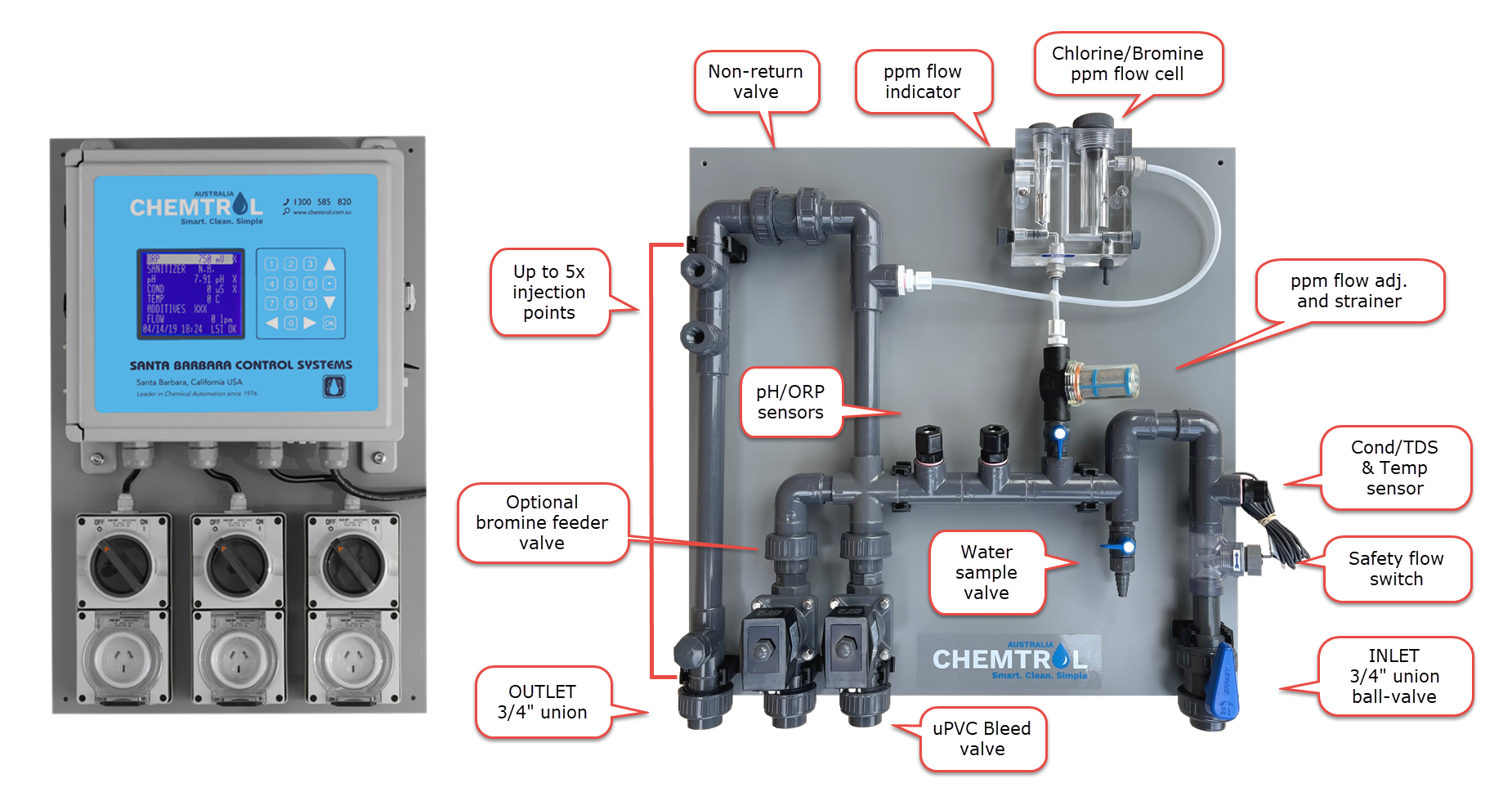

MODEL C

CT110/PC110x Programmable controller

Conductivity/TDS with Free bromine (ppm) control, pH and ORP

– Backboard 600 x 600 mm PVC sheet.

– Extra solenoid valve for Bromine Feeder available upon request.

– Up to 5 injection points of programmable chemical additives – such as inhibitors, biocides, dispersants, etc.

MODEL D

CT110/PC110x Programmable controller

Conductivity/TDS with pH, ORP & inline Fluorometer sensor for Inhibitor control

– SS Skid for a complete cooling tower system: 1800 x 600 x 800 mm.

– GPO’s ready for dosing pumps connection: 600 x 600 mm PVC sheet.

– Plumbing manifold backboard: 600 x 600 mm PVC sheet.

– Actuated bleed rotary valve IP66/67.

– Extra valve for Bromine Feeder available upon request.

– 2-station corrosion coupon rack: 600 x 400 mm PVC sheet.

– Up to 5 injection points of programmable chemical additives – such as inhibitors, biocides, dispersants, etc.

CT Programmable controller setup

- Indoor solution: GPOs ready for dosing equipment connection

- Outdoor solution: Series 56 GPOs ready for dosing equipment connection

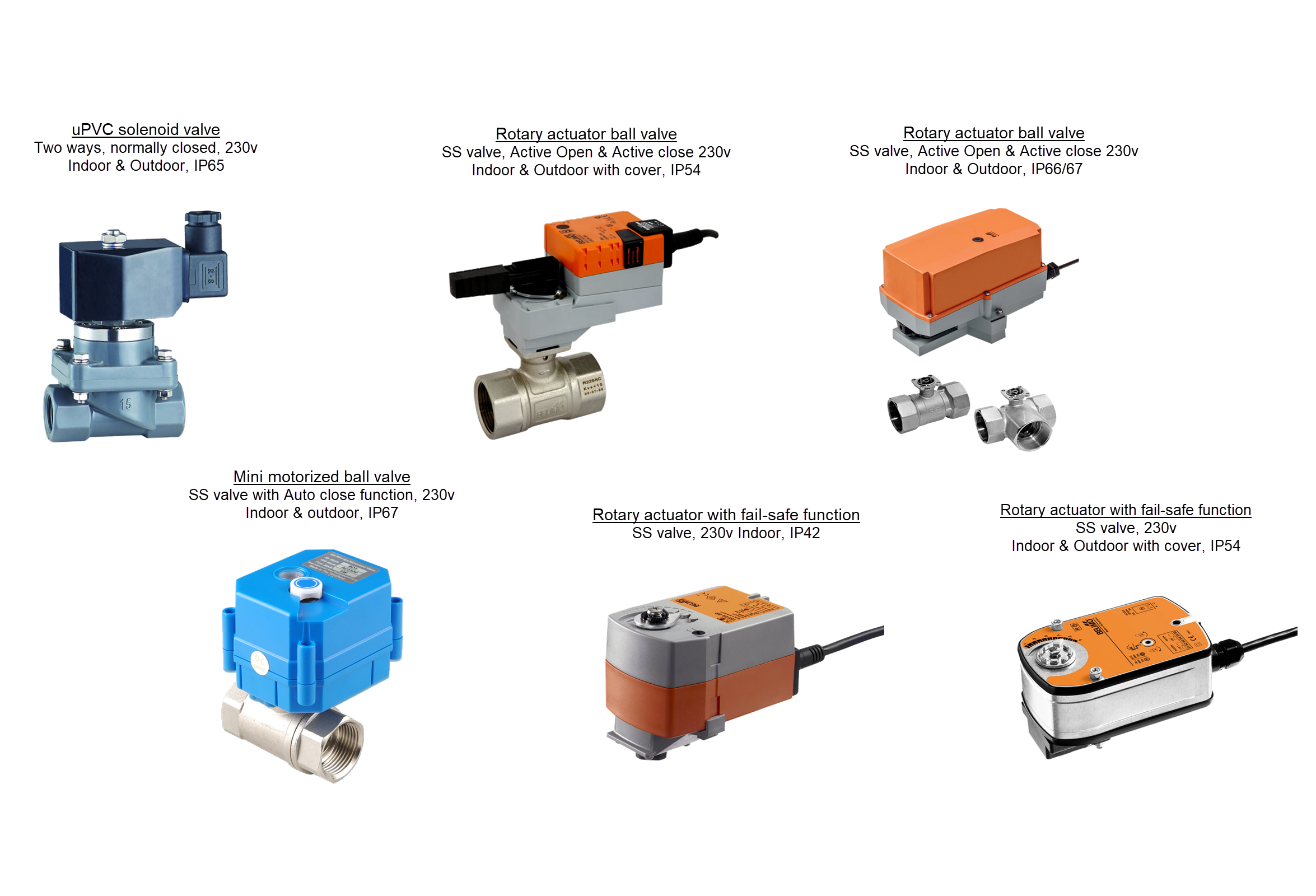

Bleed Valves Options

Indoor & Outdoor

√ uPVC solenoid valve, two ways, normally closed, 230v. IP65

√ Mini motorized ball valve, SS valve with Auto close function, 230v. IP67

√ BELIMO Rotary actuator ball valve, SS, Active Open & Active close, 230v. IP66/67

Indoor & Outdoor with cover

√ BELIMO Rotary actuator ball valve, SS, Active Open & Active close 230v. IP54

√ BELIMO Rotary actuator with fail-safe function, SS valve, 230v. IP54

Indoor

√ BELIMO Rotary actuator with fail-safe function, SS valve, 230v. Indoor, IP42

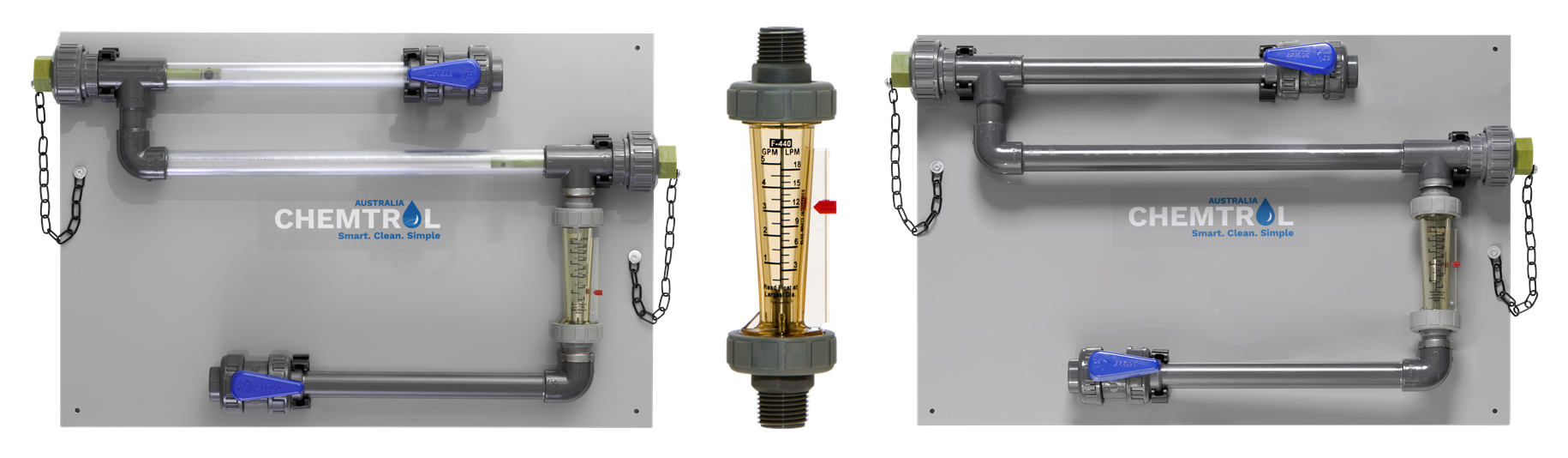

Plumbing Manifold with Mini Motorized Ball Valve

Valves Option Available

√ uPVC solenoid valve, two ways, normally closed, 230v. IP65

√ Mini motorized ball valve, SS valve with Auto close function, 230v. IP67

CHEMTROL® Corrosion Coupon Racks

uPVC and Clear PVC coupon holders. 2-4 stations with Flowmeter 5 to 37.5 LPM.

Tough Polysulfone meter body (made in USA) resists high temperatures and pressures.