Chlorine ppm Sensors

- Product Details

- Tech. Specifications

- Installation

- Maintenance

- Amplifier

PPM Sensor for CHLORINE level measurement

CHEMTROL® is introducing a new line of PPM sensors for direct measurement of CHLORINE in water in parts per million (ppm) or milligrams per litre (mg/l).

Unlike other chlorine sensors on the market, our solid state sensor features superior precision and control of free chlorine levels, with industry-leading reliability and low maintenance requirements.

Chlorine sensors – A Choice of Range

These amperometric sensors are very precise and so reliable that they are covered by a 2-year warranty. They are easy to install and practically maintenance free.

The PPM sensor can be used alone or in combination with an ORP sensor to give the operator complete control of water quality.

New membrane-less sensors are also available for Chlorine Salt Generators.

A Choice of Range

0…2 ppm

| Sensor Item# | Measuring Range | Description |

|---|---|---|

| PPMFC002 | 0… 002 PPM | |

| PPMTC002 | 0… 002 PPM | |

| PPMAC002 | 0… 002 PPM | |

| PPMBR002 | 0… 002 PPM | |

| PPMOZ002 | 0… 002 PPM | |

| PPMCD002 | 0… 002 PPM | |

| PPMAC002HP | 0… 002 PPM |

0…10 ppm

| Sensor Item# | Measuring Range | Description |

|---|---|---|

| PPMFC010 | 0… 010 PPM | |

| PPMTC010 | 0… 010 PPM | |

| PPMAC010 | 0… 010 PPM | |

| PPMBM010 | 0… 010 PPM | |

| PPMFC010S | 0… 010 PPM | |

| PPMCD010 | 0… 010 PPM | |

| PPMAC010HP | 0… 010 PPM |

0…100/200 ppm/Industrial Water

| Sensor Item# | Measuring Range | Description |

|---|---|---|

| PPMAC100 | 0… 100 PPM | |

| PPMAC200 | 0… 200 PPM | |

| PPMHP200 | 0… 200 PPM | |

| PPMPA200 | 0… 200 PPM |

* Active Chlorine Sensors – Comparison table

** These amperometric sensors are used to measure the hypochlorous acid present in hot water systems and are specially adapted for measurements under pressure (up to 8 bars). These probes are generally used for monitoring chlorination against legionella.

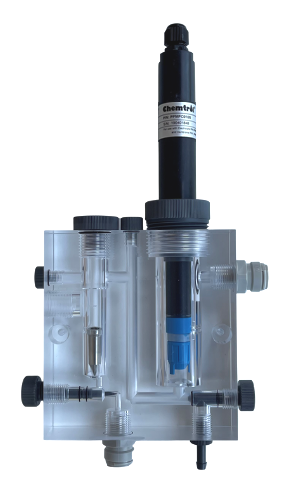

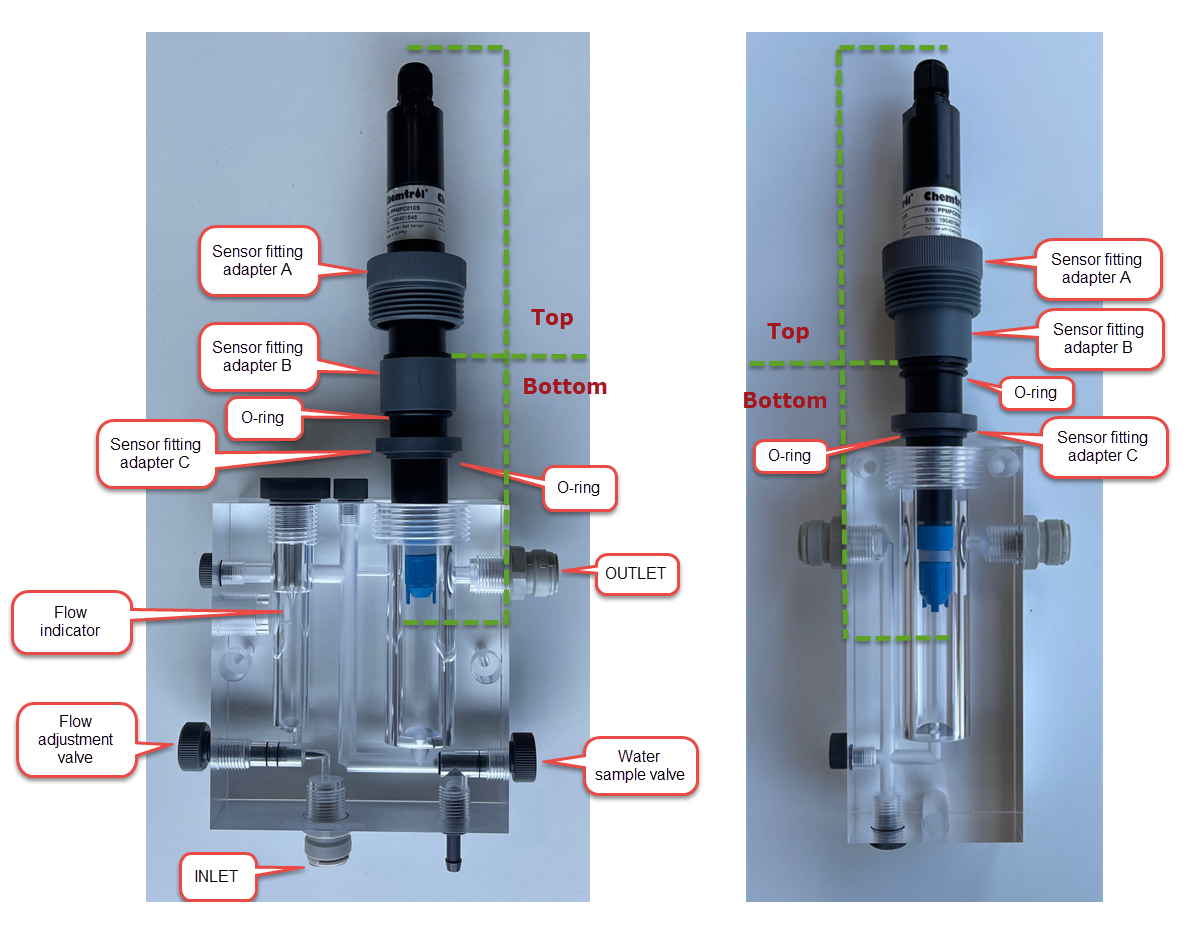

Sensor Cell Installation

The sensor is designed to be installed in a designated flow cell for controlled flow of water. The recommended flow rate is about 50 L/hr. (Approx. 1 l/min)

The chlorine sensor is shipped in a molded package containing:

One (1) chlorine sensor with serial number (needed for warranty),

One (1) chlorine sensor with serial number (needed for warranty),- One (1) compression fitting with O-ring and compression disk,

- One (1) electrolyte cap with membrane,

- One (1) electrolyte bottle and screw-on filling tip,

- One (1) screwdriver (not needed if pre-wired).

In order to prevent serious damage to the sensor, please be careful not to touch the membrane or the electrodes.

To facilitate shipment and storage of the sensor, it is not fitted with the electrolyte cap until ready for installation. The sensor cap must be filled with the electrolyte solution before usage and emptied during storage.

Fill the sensor cap with the electrolyte taking care to prevent air bubbles. Fill the cap to the bottom of the threaded section.

Fill the sensor cap with the electrolyte taking care to prevent air bubbles. Fill the cap to the bottom of the threaded section.

Thread the sensor into the cap as far as it will go. Excess air and electrolyte may escape through the hole below the rubber seal. Wipe any excess electrolyte with a soft tissue.

Slide the O-ring and the compression disk over the sensor tip up to the compression ring. Finally, insert the sensor with the compression fitting in the flow cell and make it finger tight.

Contact CHEMTROL® if you need additional electrolyte.

Flow-cell Fitting

Sensor Calibration

To calibrate the sensor, use a DPD #1 test kit for free chlorine. It is recommended to do the first calibration 2 hours after startup and to repeat it after 24 h. After that, check the calibration as required and generally every 4 weeks.

Maintenance and Warranty

There is no special maintenance requirements except to make sure that the membrane remains clean and to remove the sensor to prevent freezing in winter.

The sensor is covered with a standard manufacturer’s warranty of 2 years. Under proper water conditions, the membrane should last approximately 1 year (depending on water quality/concentration). Do not reuse the membrane if removed. Replace with new membrane.

Important information

Can we reuse a membrane?

The answer is no. Once used, it must be thrown away.

Are the electrodes really fragile?

Yes, you must not rub them. Just dub them gently.

Can the electrolyte bottle be reused once opened?

Yes, but after each use, the bottle must be well closed. It can be used before the expiry date. For information, a bottle can fill up to 3 membranes.

Should the membrane be fully tightened when mounted on the probe?

Yes, it is very important to screw it until you cannot tighten it anymore.

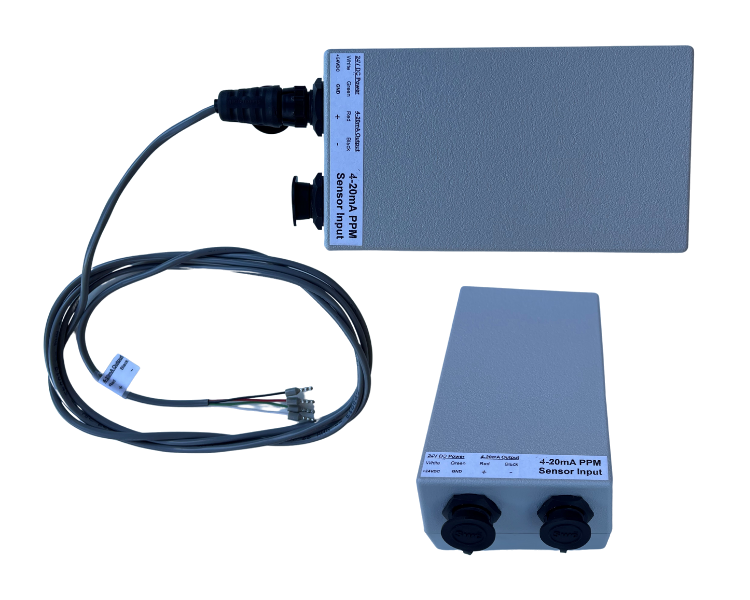

ppm Amplifier Enclosure

Designed to connect Chlorine ppm sensors with other PLCs, CHEMTROL® is introducing a ppm amplifier enclosure to support 4-20mA signal output, as well as connection to 24vDC.

A certain amount of isolation is required when measuring water attributes with electronic equipment. Stray ground currents between the sensor in water and the earth grounded PLC will affect the signal. One of the benefits of our amplifier unit is providing this isolation.