Understanding water chemistry for indoor swimming pools

Everything you need to know for clean, safe water

If you run an indoor swimming pool, like a private swim school or large public swim or spa facility, having clean, clear water is essential to protect the health of your users. There are also public health regulations governing the water quality of swimming pools and spas which must be met, as well as mandatory requirements around the frequency of pool testing.

Key measurements for indoor pool water chemistry, including pH, free chlorine, total chlorine, ORP & TDS

If you’re looking to better understand the chemistry of your indoor pool, or need to replace your dosing equipment it is important to get your head around some key concepts. This will not only help you keep your facility running smoothly, but it can also help you make an informed decision when it comes to selecting the right equipment for your swimming pool.

Let’s start with an overview of some basic pool chemistry.

Understanding basic pool chemistry for clean, safe water

Chemically balancing

Your pool water ensures it is neutral to bathers, doesn’t damage your pool surface or your pool equipment. There are 3 main elements to keeping the water in your indoor swimming pool balanced:

- pH: the ideal pH of your pool should be between 7.2 to 7.6 pH.

- Alkalinity: The ideal range for alkalinity is 60 to 200 parts per million (ppm).

- Calcium hardness: The ideal range for dissolved calcium is 80 to 500 parts per million (ppm).

The pool also needs to be sanitized so it is clean and free of bacteria, algae and other organic contaminants. The most common sanitisers or disinfectants used are chlorine, bromine, ozone, ionisers and salt chlorination.

The final element in keeping water safe and clean for users, is to continually circulate and filter the water, via a pump and sand, fabric-lined cartridge or Diatomaceous Earth (DE) filter.

Chlorine is the most common product used for sanitisation, so let’s look at some FAQs around this like: What is free chlorine? What is total chlorine? What is combined chlorine and how can we control it?

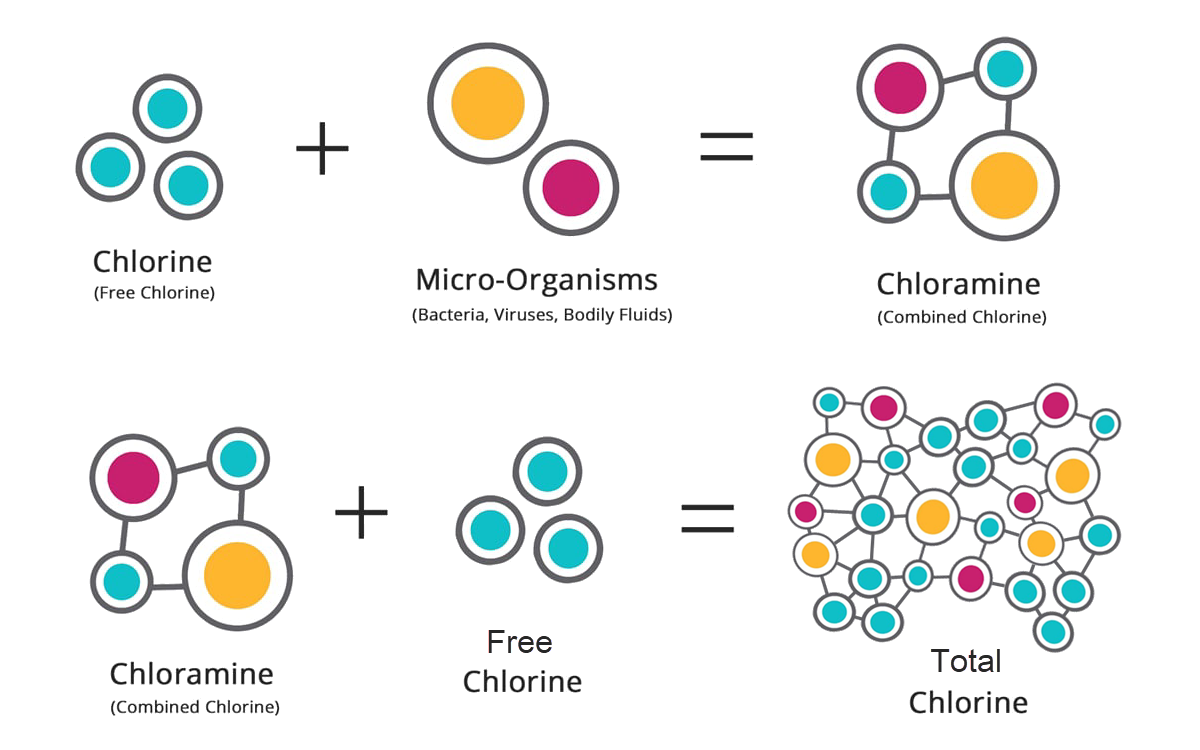

Understanding the difference between combined, free and total chlorine

Chlorine’s job is to clean your pool of germs, bacteria and algae. It is popular because it is cheap and widely available, but it is volatile, loses effectiveness quite rapidly and leads to high pH levels.

The key to keeping your pool clean or sanitised is understanding the difference between free and total chlorine.

- Free chlorine – is the amount of this sanitiser in your pool water after it has dissolved (and formed hypochlorous acid). You should aim for a level of between 1 to 3 parts per million (ppm) free chlorine in your pool water.

- Combined chlorine – is what is produced when the free chlorine reacts with all the contaminants in the water.

- Total chlorine – is the total of free and combined chlorine in your pool water.

For your pool water to be sanitised and clean, free chlorine levels must remain higher than combined chlorine levels.

Image sourced by poolonomics

Let’s now look at what key measurements we need to be aware of when it comes to water chemistry.

Key measurements for indoor pool water chemistry

You can only make precise decisions on dosing your indoor swimming pool and treatment if you have accurate and consistent measurement of key elements of your water quality.

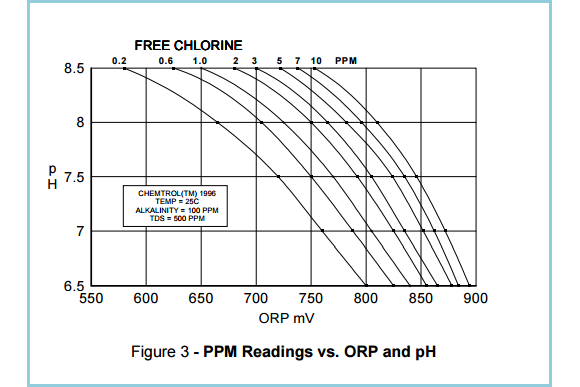

Traditionally water chemistry measurements are focused on pH and ORP.

- pH gives you an indication of the relative acidity or alkalinity and allows you to make sure the pool water is balanced.

- Oxidation-reduction potential (ORP) measures the ability of the water to break down contaminants to sanitise the water.

In NSW there is legislation in place detailing the required ORP levels in chlorine disinfected pools (at least 720 mV), where an ORP system is installed. But an ORP reading alone is inadequate for maintaining optimal hygiene in a public facility. One also needs to have constant chlorine concentration readings, typically expressed as a PPM (parts per million) value. Thankfully modern digital dosing controllers provide better visibility of water chemistry and allows us to view and utilise a combination of baseline data and measurements.

Why?

First and foremost this allows us to ensure we keep pH between the parameters of 7.2 to 7.6 pH. We also need to control the free chlorine (ppm) to ensure there is sufficient sanitiser present. In Australia health regulations governing public facilities stipulate free chlorine levels should be at 3.0 ppm or mg/per litre.

Let’s take a closer look at a few of these parameters, including PPM, ORP and TDS.

PPM and ORP – now you can have both!

Programmable controllers with a PPM sensor allow us to view free chlorine levels, while an ORP sensor provides an indication of the sanitiser level. Most swim school operators and commercial pool owners know that ORP cannot be trusted to completely control free chlorine. However, we can use this sensor as a backup to show us whether our pool has sufficient sanitizer levels or not.

This is relevant when a free chlorine sensor requires replacement, a process that can take a few days to complete. During this time the ORP sensor acts as a backup to help keep the pool sanitised with sufficient chlorine. It is not as accurate as a free chlorine sensor, but the ORP sensor gives us peace of mind until the automated dosing of chlorine resumes.

Let’s now understand why total dissolved solid levels (TDS) are important in indoor pools.

Why are total dissolved solid levels (TDS) important in indoor pools?

While outdoor pools get water replacement from rain, indoor pools do not enjoy this benefit and suffer from high TDS that builds up over time. This is especially true for public facilities with a high bather load.

Total dissolved solids (TDS) is a measure of all the dissolved substances in your water. These could be chlorides and minerals like calcium and magnesium, but also carbonates, bicarbonates and body wastes. Controllers measure total dissolved solids (TDS) in parts per million (ppm), with the normal or target range of 1000 to 2000 ppm TDS.

TDS values above 2500 ppm can lead to damage to pipes, filters and pumps, loss of water clarity and reduced chemical efficiency. High TDS values are also often the reason why your chlorine consumption increases. When TDS readings above 2500 ppm, water should be dumped and replaced with fresh water until the target level is reached.

Now that we understand why it is important to record these readings in our indoor pool, let’s choose an automated controller that can record all this data.

Choosing the right automated controller for your indoor pool

There are many automatic controllers operating in our industry. Some have pH and ORP, some have pH and free chlorine, and some even have pH with free and total chlorine sensors.

CHEMTROL® automated programable controllers have the capability to measure all the above-mentioned metrics, including pH, free chlorine, total chlorine, ORP, TDS and temperature. In addition our range of programmable controllers also have remote monitoring and control capability.

As a minimum we recommend measuring the following at a commercial indoor pool:

- pH to control liquid acid and/or CO2 gas.

- Free available chlorine (ppm) to control sanitiser level in ppm or mg/ per litre.

- TDS to control solids level and to avoid high chlorine consumption.

- ORP to have sanitizer reading and/or control backup

- And, if your pool suffers from high combined chlorine (Chloramine), having both free and total chlorine sensors would help you understand the combined chlorine level.

Shock treatment is a chemical booster treatment which should be performed from time to time to prevent the accumulation of noxious chemicals (chloramines) or biological forms like algae. Use our auto shock treatment menu to reduce the combined chlorine level.

Ultimately having oversight over all these features gives you peace of mind that the bathers in your indoor pool are safe, and that you meet all necessary public health requirements and guidelines. There are also significant cost savings to be realised installing a fully featured controller, including using less sanitiser, water and energy.