CH250 ORP/pH Digital Controller

- Product Details

- Specifications

- Installation

- Operation

Sanitizer and pH Control Made Easy

CHEMTROL® CH250 is a microprocessor-based digital controller designed to maintain both sanitizer ORP (oxidation-reduction potential or Redox) and water pH in Residential Pools and Spas, Commercial Pools and Spas, Hotels, Motels, Health Clubs, Apartments Buildings, Condo associations and Industrial Water Treatment.

Simplicity of installation, Compatible with all common sanitizers and oxidizers, ease of use and long-term reliability.

Standard Features

- Easy to install, Simple to use

- All Control Functions on Front Panel

- Sanitizer control

- pH control

- Separate Adjustable Set-points

- Separate Adjustable Alarms

- Out-of-range alarms

- Acid/Base Selector

- Proportional Feed with Adjustable Bandwidth

- Separate Adjustable Overfeed Safety Timers

- Waterproof Cabinet with Clear Window Cover

- 5-year Electronics Warranty

CH250 Specifications

| ORP Control | Adjustable from 200 to 999 mV |

| pH Control | Adjustable from 0.0 to 14.0 |

| ORP Sensor | Platinum electrode with 3 m cable |

| pH Sensor | Glass electrode with 3 m cable |

| Readouts | ORP (3 digits) and pH (2 digits) LEDs |

| Feed Mode | Manual, automatic, proportional |

| Adjustments | Set-point, calibration, limits, feed rate |

| Indicators | LEDs for feed mode, feed status, alarms |

| Safety | Audio, visual and remote alarms, out-of-range limits and overfeed safety timers |

| Cabinet | Polystyrene 22 x 18 x 10 cm |

| Electrical | 230V or 24 VAC (specify) |

| Warranty | 5 years on electronic module |

CH250 Installation

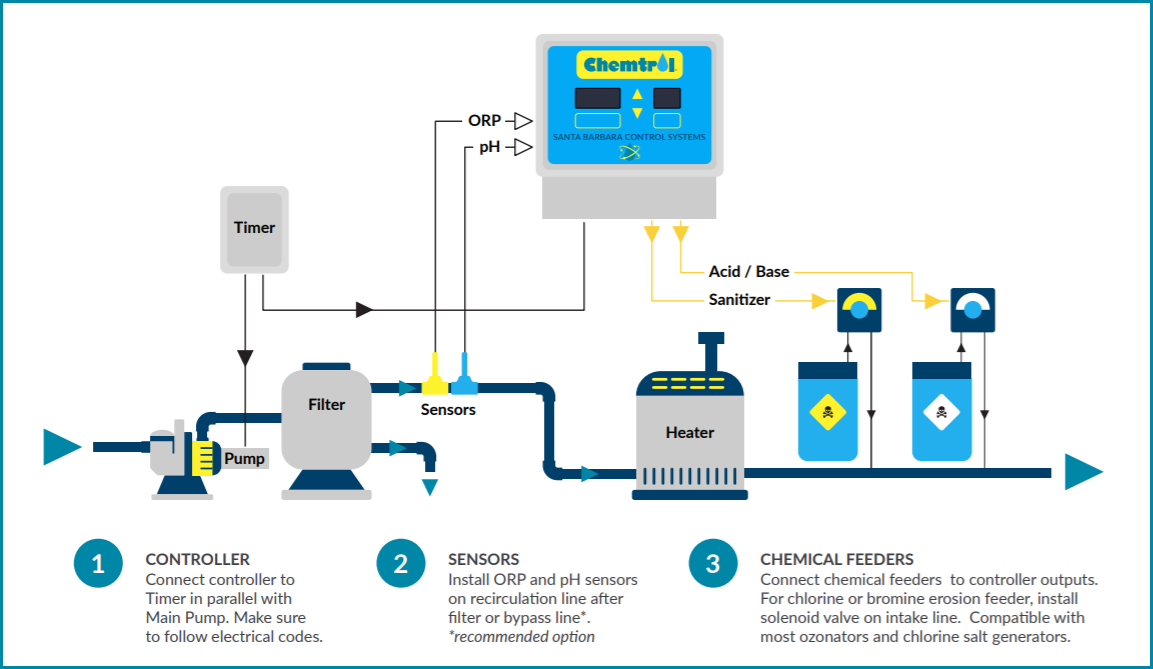

CONTROLLER

Connect the controller to 230V output of the Timer in parallel to the re-circulation pump. This will prevent accidental feeding of chemicals when the pump is not running. Make sure to follow the electrical code.

SENSORS

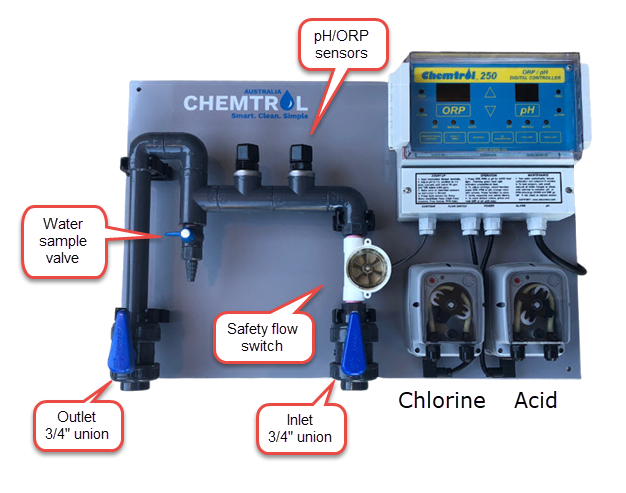

Install the ORP and pH sensors on the re-circulation line or on the optional bypass line. The two sensors can be mounted directly on the main re-circulation line with 2″ PVC tees, as shown on the schematic. For re-circulation lines over 2″ in diameter lines, the sensors should be mounted on a 1/2″ bypass line.

CHEMICAL FEEDERS

Connect the chemical feeders to 230V controller outputs, according to the manufacturer’s instructions, making sure to inject the chemicals downstream of the sensors. For a bromine or chlorine erosion feeder, install a corrosion-resistant solenoid valve on the intake line of the feeder. The controller is compatible with most ozonators and electrolytic generators.

CH250 Digital Controller

By-pass line assembly | pH and ORP control

CH250 Operation

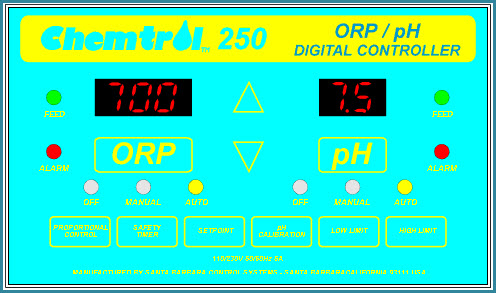

The CHEMTROL® 250 ORP/pH Digital Controller automatically maintains both sanitizer ORP (oxidation-reduction potential or Redox) and water pH in pools and spas.

All operating functions are clearly labeled and accessible from the front panel, with many safety and easy-reset features not found on other controllers:

- pH calibration from 4 to 10,

- ORP setpoint from 400 to 900 mV,

- pH setpoint from 4 to 10,

- ORP and pH feed modes: off, manual, automatic,

- ORP and pH proportional control bandwidth from 0 to 100% of the setpoint,

- ORP high and low alarms from 400 to 900 mV,

- pH high and low alarms from 4 to 10,

- ORP overfeed safety timer from 0 to 999 minutes,

- pH overfeed safety timer from 0 to 99 minutes.

To select a function, simply press ORP or pH and then the desired function. The display shows the current function value. Use the UP or DOWN arrows to adjust to the desired value.

Control Setpoints

The standard factory-set ORP control level is 700 mV, based on WORLD HEALTH ORGANIZATION (WHO) values for prevention of germs and bacteria.

The standard factory-set pH control level is 7.5. Below 7.4, the water causes eye irritation and corrosion of equipment. Above 7.6, it also causes eye irritation plus water cloudiness, scaling, stains and reduced sanitizer efficiency.

To change the control levels, the operator presses ORP or pH and then SETPOINT. Use the UP or DOWN arrows to adjust the ORP and pH setpoints. To save the new setpoint value and exit, press SETPOINT again.

The controller then automatically activates the chemical feeders for sanitizer and acid (or soda) feed, as required to maintain the set ORP and pH levels – regardless of fluctuations in bather load, contamination and weather. Like a thermostat maintaining a constant temperature, it prevents overfeeding or underfeeding, both of which are detrimental to good water quality.

Alarms

When there is an alarm condition, the corresponding display flashes the alarm value:

- ORP out-of-range,

- pH out-of-range,

- ORP overfeed,

- pH overfeed.

The display stops flashing when the condition is corrected. To reset the overfeed timers, turn the feed mode to off and then back to Manual or Auto.

Reset

The ideal values are set as default values. They can be adjusted by the operator at any time. To reset all factory default values, press ORP and pH for 5 seconds.