Smart

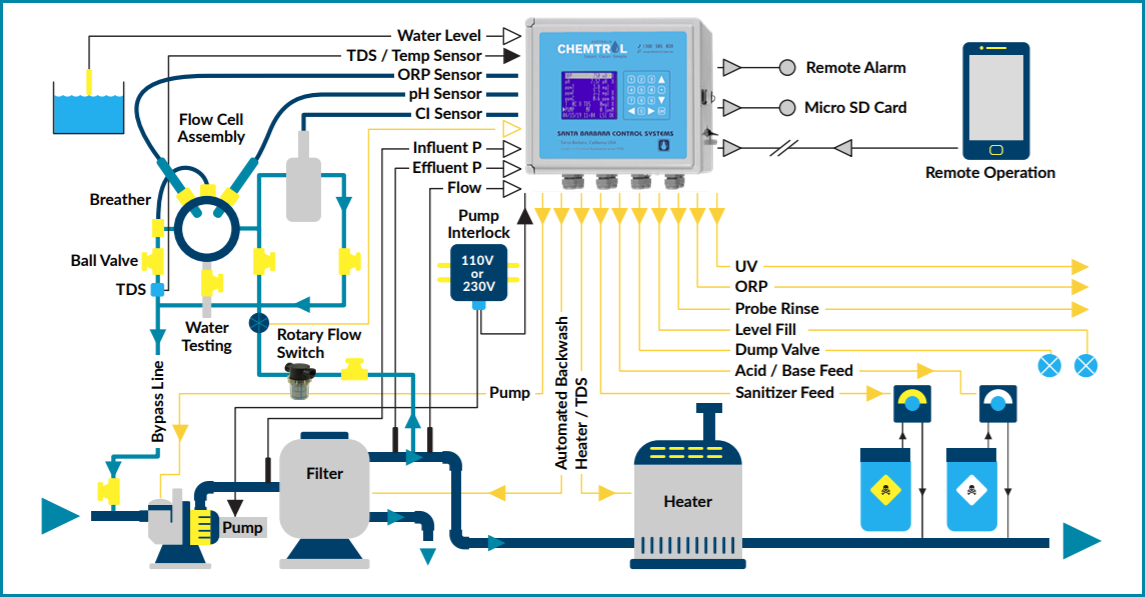

SMART control via a single integrated command centre that incorporates all the control, monitoring and communication functions for your water treatment control and chemical automation needs

Advantages of Integration

The new concept of Integrated Water Treatment combines all the required control functions for water treatment into a single command center. Introduced by CHEMTROL® since 1996, this unique method is influencing the design of aquatic facilities.

The first advantage of integration is the simplicity of installation with all sensing and control components connected to a central unit. Another advantage is ease of operation for the operator with all operating functions displayed on one large Display Screen located on the front panel of the controller.

From an operational standpoint, there is another significant advantage in the increased safety of operation due to the interrelationship between the different control mechanisms. For instance, during back-washing operations, the chemical feeders are automatically disabled to prevent accidental overfeeding. Similarly, before the main re-circulation pump is shut down, the heater is first turned off to allow for cool-down of the heating elements (fireman delay).

Integrated Water Treatment

The CHEMTROL® PC7000 and PC7100 Integrated Controllers incorporate all the monitoring, control and communication functions into a single integrated command centre designed around a powerful microprocessor:

√ Chemical Automation with sanitizer and pH control,

√ Water Balance with display of the Langelier Saturation Index and automatic control of conductivity or Total Dissolved Solids (TDS),

√ Heater Control with automatic temperature control and energy saver program,

√ Pump and Filter Control with weekly pump operation program and automated sequential back-washing of single or multiple filters,

√ Remote Monitoring and control with our smart Web-server, offers true duplex operation with identical duplicate screens on both the controller and the computer.

Water Treatment

Water treatment for swimming pools, spas and industrial applications requires the combination of physical and chemical processes, including pumping, filtration, chemical treatment, heating and water replacement. Up to now, the processing equipment was made by different manufacturers and controlled individually, resulting in complicated and inefficient system installation and operation.

The CHEMTROL® PC7000 and PC7100 Integrated Controllers incorporate all the monitoring, control and communication functions into a single integrated command center designed around a powerful microprocessor.

The integrated Main Screen display enables the operator to supervise all the process functions at a glance and to quickly respond to any changing condition. These controllers operate like a computer with full-screen displays and direct-access menus and sub-menus.

The front panel keypad is used to move up and down each menu and enter or exit the sub-menus. All operating functions can be easily modified from the keypad, including sensor calibration, control set-points, alarm levels and the programs for super-chlorination, sequential back-washing, chemical saving and energy saving.

Remote monitoring

Our range of programmable controllers all have remote access capability, so you can control and monitor your facility 24/7.

With the remote operation function any number of facilities can be controlled and monitored from your computer, or via our mobile App. From a computer simply login directly via your browser using our web-server where the controller display is mirrored on your computer. True duplex operation that allows real-time control and troubleshooting of all operating functions, including status reports, trend graphs and automatic alerts by email or text messages.

You can also access and control your controller via our dedicated app, available for Android and Apple devices.

In terms of connecting your controller, this can be achieved via a wired Ethernet cable, WIFI signal, or by using a wireless connection with a compatible 4G or 5G router. Find out more: web-access options.

Chemical Automation

“By constantly monitoring the pH of the water and the activity of the sanitizer, makes it possible to maintain clean and safe water at all times with a significant reduction in the cost of chemicals, maintenance and repairs.”

It is now recognized as a must for all commercial and public pools and spas, as well as for quality residential installations.

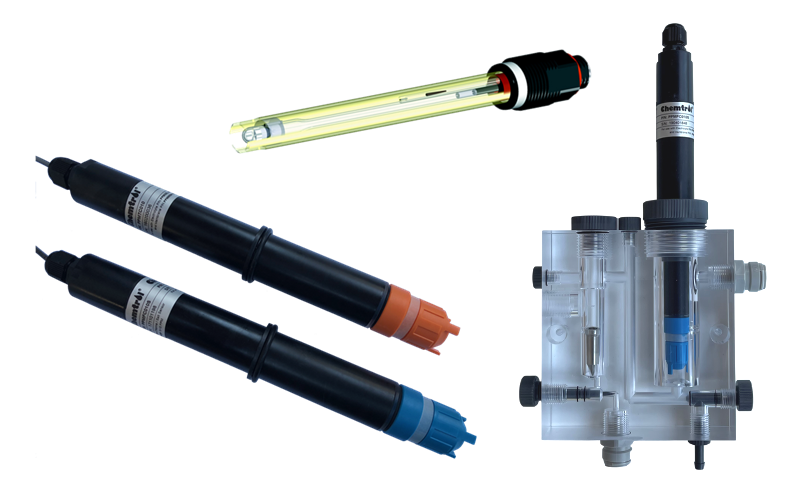

ORP is used to monitor the Oxidation-Reduction Potential in the water produced by a true oxidizer, like ozone, or an oxidizing sanitizer, like chlorine or bromine.

The ORP MENU includes selection of the control mode (Off, Manual, Auto or Timer), sensor calibration (1, 2 or 3 points), set-point level, high and low alarms, shocking and chemical saver programs. It also displays the run time for the current feed event and cumulative run time. Shock treatment can be initiated manually or under programmable weekly or multi-weekly schedules.

The SANITIZER MENU is used to control the chlorine or bromine level in terms of sanitizer concentration (parts per million or milligrams/liter), obtained by conversion from ORP and pH values using a proprietary algorithm or from an amperometric sensor. The sanitizer concentration readings can be calibrated to account for the effect of cyanuric acid stabilization. Superchlorination can be initiated manually or under programmable weekly or multi-weekly schedules.

The pH MENU is used in the same way to select the pH control parameters using either acid or base feed or both. It also includes an Acid Wash program for periodic injection of an acid rinse solution to clean the heads of the sensors.

Saturation and Water Balance

Proper control of Saturation and Water Balance is required to maintain water quality and to avoid the development of scaling or corrosive conditions. Up to three different types of chemical additives – such as inhibitor and biocides for cooling towers – can be programmed separately for automatic addition as a function of time, bleed activation, pH control activation or cumulative flow rate.

The Conductivity sensor monitors the concentration of dissolved solids by measuring the conductivity of the water. The data can be displayed either in conductivity units (microsiemens/cm) or in parts per million of Total Dissolved Solids (TDS), using an operator-selectable conversion factor.

The CONDUCTIVITY MENU is used to set automatic dumping (bleeding) of water when the dissolved solid concentrations becomes too high, selecting either a Conductivity or a TDS control set-point to activate the dump valve. Backfilling of water is done simultaneously with a level control activated valve.

The Langelier Index calculates the saturation condition from the pH and Temperature sensor inputs and from manual data entry for Alkalinity and Calcium Hardness. The water saturation condition is constantly displayed on the Main Screen as either “OK”, “Scaling” or “Corrosive” using standard Langelier Index limits. If a scaling or corrosive condition develops, it is immediately indicated with a flashing display on the Main Screen. “What if” analyses can be run at any time by manually entering different values for alkalinity, calcium hardness, pH and temperature.

Temperature and Heater Control

Temperature Sensor readings are displayed either in degrees Fahrenheit or Celsius and used to control the heater. The HEATER MENU is used to set the heater control to Manual or Automatic using a programmable seven-day schedule with separate daily ON and OFF times. The energy saver program is used to lower the water temperature during hours when the facility is not in use, thereby realizing substantial savings on heating costs.

Pump and Filter Control

Filtration control includes manual or programmable operation of the main recirculation pump and back-washing cycle using data input from the flow sensor and from the influent and effluent pressure sensors. This eliminates the need for the more expensive and less reliable mechanical sequencers used in traditional filter rooms.

With the PUMP CONTROL, the main re-circulation pump can be set to Manual for continuous 24-hour operation or to Automatic with a seven-day schedule. Protection of the heater is assured with the adjustable fireman delay to allow for cool-down of the heater before water re-circulation is stopped.

The FILTER CONTROL is used to program the backwash schedule based on time cycle or on pressure differential. Multiple filters are back-washed in sequence with adjustable backwash and advance time for each filter. Electrical, hydraulic or pneumatic valves can be used to distribute the water flow through the different filters.