PC110 Programmable Controller

- Product Details

- Specifications

- Installation

- Operation

Simple, reliable and flexible programmable controller

Suitable for: Commercial pools and spas, water features & water parks

The PC110 Programmable Controller is a versatile solution for ensuring the water quality and chemistry of swimming pools & spas, water features and water parks. It has a user-friendly interface that features multiple timers, sensor inputs, and 6x control relay outputs enabling precise automation of water chemistry.

The unit’s robust design ensures reliable and efficient operation and automatic maintenance of water chemistry. Free chlorine sensor with direct reading in PPM or mg/l, ORP monitoring for sanitizer reference and oxidizer control backup, pH control with a choice of acid/co2 or base feed, as well as TDS control with temperature monitoring.

Key features of the PC110 include:

Remote access: You can control and monitor your pool or spa via our app, from anywhere at any time – using a computer, tablet or mobile device.

pH control: a choice of acid/co2 or base feed. Dedicated setpoint and relay output for both co2 & Acid.

Programmable super-chlorination + chemical savings cycles: The PC110 can be programmed to automatically perform super-chlorination cycles to shock your pool or spa, or to reduce the amount of chemicals you use by scheduling chemical feed cycles during off-peak hours.

Display of the Langelier Saturation Index: The Langelier Saturation Index is a measure of the potential for scale or corrosion to form in your pool or spa. The PC110 can display the Langelier Saturation Index so you can easily monitor the condition of your water.

5 Year warranty: The PC110 is backed by a 5-year warranty, which is industry-leading cover for your peace of mind.

Enquire now: sales@chemtrol.com.au

Or call us on: 1300 585 820

Chemical Automation includes chlorine level (ppm), pH, ORP and TDS

| Control Relay Output | 6x control relay outputs enabling precise automation of water chemistry |

| Chlorine Control (PPM) | Free or Total chlorine sensor 0 to 10 ppm with direct reading in PPM or mg/l |

| pH Control | A choice of acid/co2 or base feed, 0 to 14. Dedicated setpoint and relay output for both co2 & Acid |

| ORP Control | ORP monitoring for sanitizer reference and oxidizer control backup 200 to 999 mV, Set-point for oxidizer or reducer |

| TDS Control | Salt level monitoring for chlorinators 0 to 20,000 mg/l with optional dump valve |

| Temperature Readout | Temperature monitoring and display, from -18 to 60 C |

| Shock Treatment | Programmable super chlorination & Chemical saving cycles |

| Langelier Index | Calculated from pH, Temp, Total Alkalinity and Calcium Hardness. Water Balance display |

| Sensor Calibration | 1, 2 or 3 points |

| Control Modes | Off, Manual, Automatic, Timer, ON/OFF or Proportional Feed |

| Automatic Data Logging | Micro SD card for easy program updates and automatic data logging |

| LCD Display | Large 8-line LCD DISPLAY for easy operation |

| Remote Alarm | High/low, out-of-range, run time and overfeed Visual, audio and external alarms |

| Bypass line Assembly | Flow Cell Assembly (FCA) designed specifically for pool and spa applications with safety flow switch |

| Patented Probe Alert Safeguard | Dynamic probe testing with sensor failure warning |

| Mechanical | 34 x 29 x 17 cm, Rain and splatter proof NEMA type 4x Cabinet |

| Electrical | 10A 110/230 V with selector switch, all output and alarm relays 5A |

| Approvals | UL, NSF 50 and CSA Approved |

| Warranty | Controller: 5-year electronics warranty Sensors: 2-year warranty |

Options available

- FLOW: Flow monitoring & totalizer with electronic sensor and adjustable alarms.

- ETHCOM: CHEMTROL® web-server communication – remote monitoring and control with identical duplicate screens technology.

- 420M: 4-20mA signal (4-channels) for monitoring display outputs.

- BMS: Modbus/BACnet protocol communication for Building Management Systems.

PC110 Installation

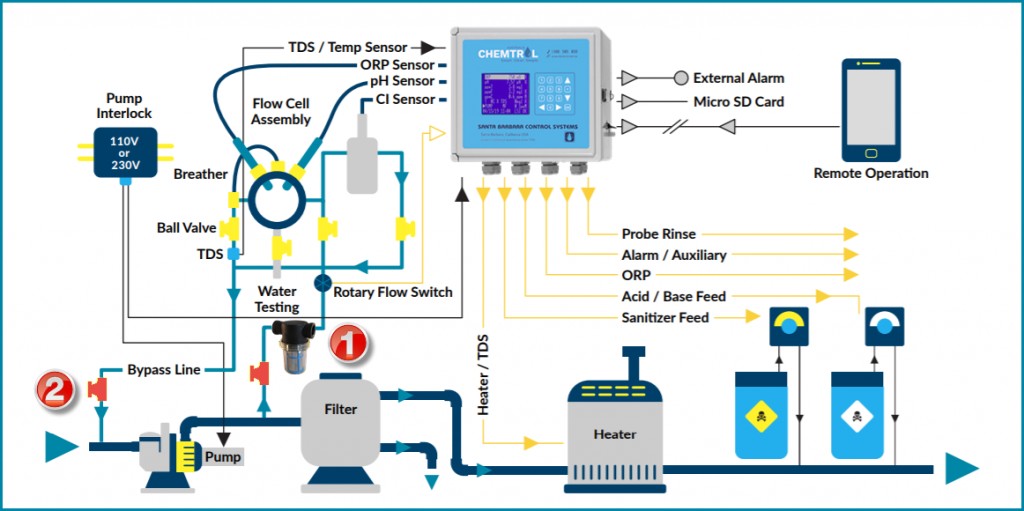

In our commitment to simplify the installation process of CHEMTROL® controllers, we have streamlined everything onto a customized assembly manifold, prepared for easy connection.

This approach ensures proper water sampling around the sensors, facilitating a hassle-free installation that minimizes the integration work required to get your water treatment system operational.

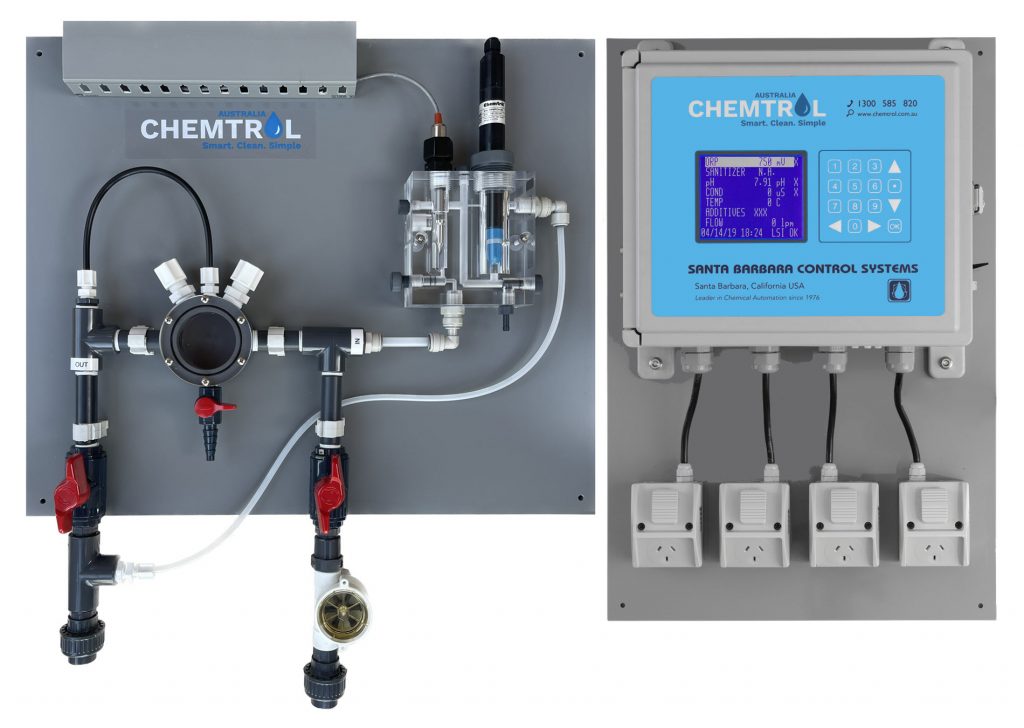

PC110 – Bypass line assembly

Chlorine sensor (ppm) with integrated pH, ORP, and TDS control

Seamless controller setup: Choose between hardwired dosing pumps or General Purpose Outlets (GPOs) for easy dosing equipment connection.

Our Flow Cell Assembly (FCA) features a clear acrylic flow cell for Chlorine sensor (ppm), 2 flow control valves, a water sample valve, safety flow switch, and probes holder fitting.

The Controller assembly comprises a grey PVC backboard (600×400 mm), while the By-pass line assembly measures (600×500 mm).

PC110 Operation

The CHEMTROL® PC110 controller functions like a computer, featuring an LCD screen display and direct access to all menus and sub-menus. Navigating through menus is seamless with the front panel keypad, allowing users to move up and down each menu and enter or exit sub-menus effortlessly.

The keypad enables easy modification of all operating functions, including sensor calibration, control set-points, alarm levels, and various feed programs.

Remote Monitoring & Control

Our range of programmable controllers all have remote access capability, so you can control and monitor your facility 24/7.

With the remote operation function any number of facilities can be controlled and monitored from your computer, or via our mobile App. From a computer simply login directly via your browser using our web-server where the controller display is mirrored on your computer.

True duplex operation that allows real-time control and troubleshooting of all operating functions, including status reports, trend graphs and automatic alerts by email or text messages. You can also access and control your controller via our dedicated app, available for Android and Apple devices.

True duplex operation that allows real-time control and troubleshooting of all operating functions, including status reports, trend graphs and automatic alerts by email or text messages. You can also access and control your controller via our dedicated app, available for Android and Apple devices.

In terms of connecting your controller, this can be achieved via a wired Ethernet cable, WIFI signal, or by using a wireless connection with a compatible 4G or 5G router.

Find out more: web-access options.