FLEXFLO® A2

- Overview

- Product Details

- Specifications

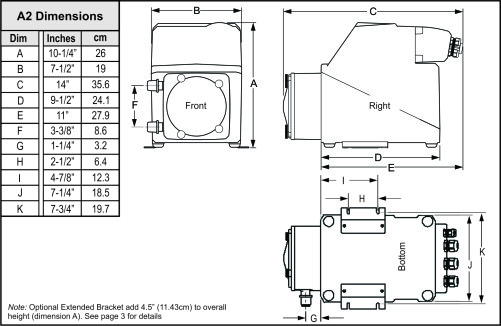

- Dimensions

- Video

- TFD

FLEXFLO® A2 Series Peristaltic Pump for high pressure and high accuracy applications.

Max Feed: .02 – 17.2 GPH (.07 – 65.1 LPH)

Max Pressure: 125 PSI (8.6 bar)

Simplify chemical feed with the FLEXFLO® A2 Peristaltic Metering Pump. This rugged and compact pump features a gentle, low-shear pumping action, making it an ideal choice for dosing shear-sensitive or gaseous fluids. The A2 does not require check valves, seals, or other ancillary equipment to function, reducing maintenance intervals and process downtime.

Remote control signal options include Remote Start/Stop, Flow Verification, Pulse, and 4-20mA.

√ 4-20mA (A2V only), Pulse Input (A2V only) and Manual Speed Control

√ Optional A2V communication protocols: Modbus, Profibus and Industrial Ethernet

√ 100:1 Turndown Ratio

√ Variable Speed DC Motor

√ NEMA 4X (IP 66) Washdown Duty

√ 2 Year Warranty

√ Flex-A-Prene® Tubing with more than 4X longer tube life.

√ Patented Tube Failure Detection (TFD) System

√ Quick Disconnect Fittings Available for Flex-A-Prene

Benefits of a Peristaltic Pump:

- Self-priming – even against maximum line pressure. By-pass valves are not required. Cannot vapor lock or lose prime.

30ft of suction lift. Gentle low shear pumping action. - Tube Failure Detection (TFD) senses tube rupture by detecting chemical in the pump head. No false triggering – Patented

- Optional dual channel tube design for optimum performance and pressure capability

Communication & Interface:

- Operator friendly digital controls with backlit LCD displays motor speed, input signal values, service, and alarm status

- Inputs include: 4-20mA and pulse inputs for remote external speed control and either powered 6-24 VDC or non-powered dry contact closure for remote start/stop

- Outputs: one 250V/3A relay to monitor TFD (Tube Failure System) and FVS (Flow Verification System), one 4-20mA analog signal scalable to the motor speed and one relay output for run status

- Compatible with Blue-White’s output Flow Verification Sensor (FVS) system. Sensor is sold separately

Superior Engineered Design:

- 2 Year Warranty

- 100:1 turndown ratio

- NEMA 4X (IP66) wash-down, chemically resistant powder coated enclosure

- Heavy duty rotor means no flexing and increased accuracy with no metal springs or hinges to corrode.

Safety Features:

- Tube Failure Detection (TFD) senses tube rupture, preventing hazardous chemical spills

Optional Components Available:

- Mounting Extended Brackets (72000-380) – 1 Pair, SS, 4 SS Screws

What’s Included:

- A2 Peristaltic Metering Pump

- Two tube assemblies

- Discharge injection fitting with check valve

- With “S” 3/8” OD x ¼” ID tubing compression type connections:

- Suction tube – clear PVC – 10′ length (3/8″ OD, 1/4″ ID)

- Suction strainer

- Suction ceramic weight

- Discharge tube – opaque polyethylene – 10′ length (3/8″ OD, 1/4″ ID)

- With “B” ½” hose barb and “M” MNPT type connections:

- Suction strainer

- #5 hose clamp (“B” Only)

- With “C” Tri-clamp and “Q” Quick Disconnect connections:

- No accessories provided

- Tube installation tool

- Mounting hardware kit

- Junction box connectors

FLEXFLO® A2 Series Peristaltic Pump for high pressure and high accuracy applications.

Max Feed: .02 – 17.2 GPH (.07 – 65.1 LPH)

Max Pressure: 125 PSI (8.6 bar)

| Max. working pressure: | 125 psig (8.6 bar) |

| Max. fluid temperature (excluding pump tubes): | 3/8” OD x 1/4” ID tubing connections: 130 F (54 C) M/NPT connections: 185 F (85 C) Note: see individual pump tube assembly maximum temperature ratings |

| Ambient Operating Temperature: | 14 F to 115 F (-10 C to 46 C) |

| Ambient Storage Temperature: | -40 F to 158 F (-40 C to 70 C) |

| Maximum fluid viscosity: | 12,000 Centipoise |

| Maximum suction lift: | 30 ft. Water at sea level (14.7 atm psi) |

| Operating Voltage: | 115VAC/60Hz, 1ph (1.5 Amp Maximum) 230VAC/60Hz, 1ph (0.7 Amp Maximum) 220VAC/50Hz, 1ph (1.0 Amp Maximum) 240VAC/50Hz, 1ph (1.0 Amp Maximum) |

| Power Cord: | 240V50Hz = AS 3112 (Australia/New Zealand) |

| Motor: | Brushed DC, 1/8 H.P. |

| Duty cycle: | Continuous |

| Motor speed adjustment range 100:1: | 1.0% – 100% motor speed (1.3 to 130 RPM) |

| Motor speed adjustment resolution: | 0.1% increments |

| Display: | Backlit LCD, UV resistant |

| Keypad: | Eight button positive action tactile switch keypad |

| Enclosure: | NEMA 4X (IP66), Polyester powder coated aluminum |

| Maximum Overall Dimensions: | 19 W x 26 H x 35.6 D cm |

| Product weight: | 12.9 Kg |

| Approximate shipping wt: | 15.9 Kg |

Tube Failure Detection (TFD) System

Patent No. 7,001,153 and 7,284,964

No False Triggering!

Breakthrough technology for Peristaltic Pumps.

The TFD system will detect a wide range of chemicals (i.e. chlorine, acids, soaps, etc.). This unique technology was designed NOT to false trigger by condensation and washdown. Many companies require the TFD system for their peristaltic pumps.