-

Cooling towers and Legionella

Cooling Towers and Legionnaires’ disease: Control, Monitoring and Prevention

A recent spike in cases of Legionnaires’ disease in NSW has highlighted the need for cooling towers used in conjunction with large HVAC systems and industrial cooling processes to be appropriately maintained and monitored. Public health regulations across Australia require any operation that have cooling towers on their premises to ensure that they are appropriately maintained for public health and safety.

This article looks at Legionnaires’ disease and its cause, its presence in cooling towers, the legislation and regulation around managing the disease – as well as what an effective water treatment plan for cooling towers looks like.

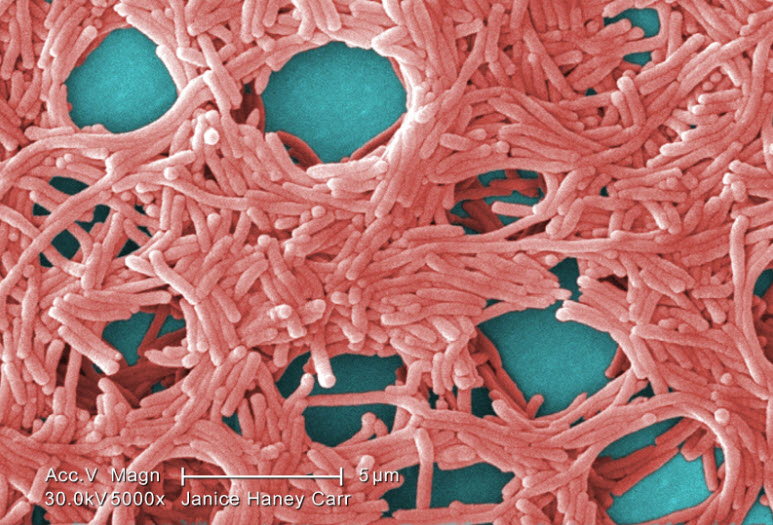

https://upload.wikimedia.org/wikipedia/commons/1/13/Legionella_pneumophila_%28SEM%29_2.jpgWhat is Legionnaires’ disease?

Legionnaires’ disease is a severe infection of the lungs not dissimilar to pneumonia. It is caused by bacteria of the Legionella family, specifically Legionella pneumophila, which can be present in air conditioning cooling towers, spas and similar bodies of water. One becomes infected by inhaling the bacteria, after which it takes anywhere from two to 10 days to become sick.

Legionnaires’ disease is a severe infection of the lungs caused by bacteria of the Legionella family

Legionella in cooling towers

Legionella pneumophila bacteria can grow to high numbers in warm, stagnant water. Outbreaks are sometimes associated with contaminated cooling towers. Legionella thrive in this environment due to a number of factors, specifically:

- Stagnant water

- Warm temperatures

- Nutrient availability

These conditions are often caused by a deficiency in the maintenance of the cooling tower. Regular inspections, disinfection and maintenance of cooling towers and plumbing systems is the only way to limit the growth of the Legionella bacteria.

Regular inspections, disinfection and maintenance of cooling towers and plumbing systems is the only way to limit the growth of the Legionella bacteria

Regulations for cooling towers and Legionella testing

The relevant Australian Standards that cover Legionella risk management are actually very basic and are supplemented by regulatory guidelines at the state level.

Some Australian/New Zealand Standards relevant to Legionella control include:

- Australian/New Zealand Standard 3666 – Air-handling and water systems of buildings – Microbial control, as well as SAA/SNZ HB32 – Control of microbial growth in air-handling and water systems of buildings.

These specify the minimum requirements for design, installation, commissioning, operation and maintenance of air-handling and water systems in buildings to assist in the control of microorganisms, including Legionella bacteria.

The regulations regarding maintenance regimes for cooling towers is actually different in every state.

NSW

Due to a recent spike in cases monthly testing for Legionella is now mandatory for all cooling tower systems in NSW, a directive that came into force on 1 January 2018. The occupier of the premises on which the cooling tower is installed is also required to report any test results that exceeds 1,000 CFU/mL Legionella to the NSW Health. Legionella control in NSW is covered by the Public Health Act 2010.Victoria

In Victoria the Public Health and Wellbeing Act 2008 covers cooling tower maintenance. It requires the owner of any land on which there is a cooling tower system to register the system, developing an RMP and have the plan independently audited by an approved auditor.Queensland

In Queensland the Work Health and Safety Act 2011 obliges owners of plant, such as cooling towers to ensure the facility is maintained in a condition that ensures the plant is safe, and without risk to health.South Australia

In South Australia the Public Health (Legionella) Regulations 2013 require, ‘system owners to conduct monthly inspections of regulated systems and ensure periodic preventative maintenance is performed as prescribed’. Cooling towers are also required to be inspected annually by Environmental Health Officers.Tasmania

In Tasmania guidelines for the control of Legionella is regulated by the Public Health Act 1997, and the Guidelines for the Control of Legionella in Regulated Systems require the owner of premises where registered systems are installed to register these, and properly operate and maintain these systems.

Effective water treatment for cooling towers

A key objective of any effective water treatment program for cooling towers should look to control and limit:

- corrosion

- scaling

- fouling

- microbial growth, including the growth of Legionella

Ideally any water treatment plan should be done under the auspices of a risk assessment management plan. Additionally the water treatment system should look to manage some specific aspects of water quality, namely:

- Conductivity/TDS

- ORP with satisfactory level for disinfection

- pH correction – always below 8.00

- and programmable chemical additives – such as inhibitors, biocides, dispersants, etc.

Modern programmable controllers enable all of these functions, and also have the additional advantage of monitoring these indicators 24/7 using remote access via an internet connection. This can provide real time alerts for scaling, corrosion, or alert the operator if anything is not working properly – such as the disinfection chemicals or an increase in ORP levels.

CHEMTROL® fully featured range of Programmable Controllers are suitable for Cooling Tower applications and come with an industry-leading 5 year electronics warranty.

Want to learn more? Our selection chart can help you decide which CHEMTROL® controller is right for your application. Or get in touch on 1300 585 820 for more information about out range.

News

- The new PC1500 range is now available

- Peristaltic metering pumps for pools and spas

- Booster backup for sanitiser + pH

- Sustainability: Cooling Towers

- New features and functionality

- Smart Web Server Upgrade

- PVDF Flow Fitting Products

- Building Control & Management Systems (BCMS)

- The Importance of Corrosion Monitoring

- CHEMTROL® Controllers Are 5G Compatible

- Total Cost of Ownership (TCO)

- Simplify the Complicated with the A1A Dosing Pump

- Dual Boiler Controller With Remote Monitoring Capability

- Sustainability: Swimming Pools and Spas

- New CT requirements NSW – 2018

- Cooling towers and Legionella

- Web Server Upgrade