-

PVDF Flow Fitting Products

TEFEN PVDF fittings: for exceptional chemical resistance, stability and purity

TEFEN PVDF fittings: for exceptional chemical resistance, stability and purity SYDNEY, NSW – 22 Sep 2020

Did you know that CHEMTROL® can supply you with PVDF connectors and flow fitting products for your facility – a high performance plastic.

PVDF – polyvinylidene fluoride – is widely used in high tech applications where exceptional chemical resistance, high purity, stability and high mechanical strength are required. For this reason it is specified in high purity water systems such as water treatment plants – for pipes, valves and connectors. It is also widely used for filtration and housing equipment. It is also valued in applications where failures associated with brittleness, chemical or abrasion resistance are prime concerns.

PVDF – polyvinylidene fluoride – is widely used in high tech applications where exceptional chemical resistance, high purity, stability and high mechanical strength are required. For this reason it is specified in high purity water systems such as water treatment plants – for pipes, valves and connectors. It is also widely used for filtration and housing equipment. It is also valued in applications where failures associated with brittleness, chemical or abrasion resistance are prime concerns.

What is PVDF?

PVDF is a semi-crystalline, superior high purity thermoplastic fluoropolymer with superior increased resistance to elevated temperatures, chemical corrosion, permeation, degradation, nuclear radiation, ultraviolet attack and growth of microorganisms.

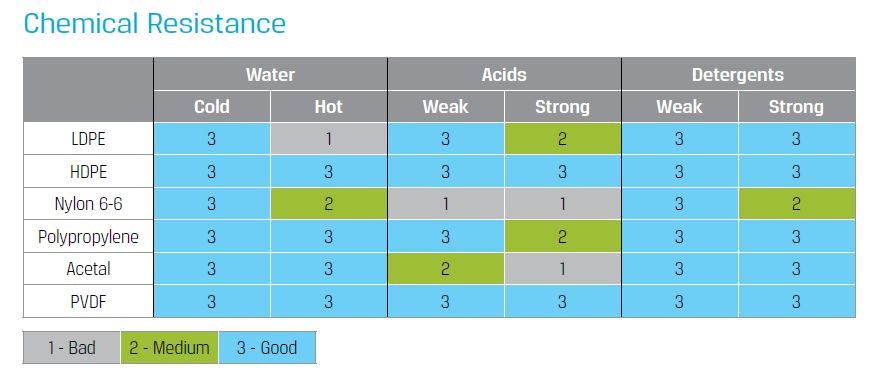

PVDF has exceptional chemical resistance combined with good mechanical strength over a good temperature range. Its best attribute is chemical resistance. For this reason PVDF fittings, connectors and pipes provide a number of benefits, including:

Stable in nature

Stable in nature- High working temperature: 145 ºC (subject to application)

- Low melting point: -20 ºC

- High working pressure: up to 14 BAR (200 psi)

- Low permeability to liquids

- Resistant to chemicals

- Non-flammable when exposed to flame

- Lowers total cost of ownership over time

PVDF is also utilised in the pharmaceutical and food processing sector, where the high purity and sanitation capability make it an invaluable surface material.

PVDF in water treatment applications

The TEFEN PVDF fittings are commonly used in water treatment applications, deionization, distillation and demineralization. They are used for their chemical resistance to handle salts / brine solutions, strong and concentrated acids, hot corrosives, aromatics, and halogen solutions such as chlorine and bromine.

PVDF vs PVC vs metals

When compared to PVC (Polyvinyl chloride) PVDF operates at higher temperatures – 145ºC vs 60ºC. PVDF also has increased mechanical durability to PVC and Chlorinated polyvinyl chloride (CPVC), and is more resistant to permeation and to a greater number of chemicals.

When compared to metal plumbing PVDF is not susceptible to corrosion, rusting or corrosion – and has a higher resistance against chemicals, including chlorine-based compounds such as hydrochloric acid and HCl. In terms of installation and costs PVDF is similar to metal and stainless steel.

Fig. 1 Chemical resistance of PVDF vs other materials.

PVDF Flow Fitting Products

CHEMTROL offers a full range of PVDF flow fitting products that include connectors, nipples, couplings, elbows, caps and more.

Call us on 1300 585 820 for a chat or visit our PVDF flow fitting page to browse our full range

-

PVDF Flow Fitting Products

News

- The new PC1500 range is now available

- Peristaltic metering pumps for pools and spas

- Booster backup for sanitiser + pH

- Sustainability: Cooling Towers

- New features and functionality

- Smart Web Server Upgrade

- PVDF Flow Fitting Products

- Building Control & Management Systems (BCMS)

- The Importance of Corrosion Monitoring

- CHEMTROL® Controllers Are 5G Compatible

- Total Cost of Ownership (TCO)

- Simplify the Complicated with the A1A Dosing Pump

- Dual Boiler Controller With Remote Monitoring Capability

- Sustainability: Swimming Pools and Spas

- New CT requirements NSW – 2018

- Cooling towers and Legionella

- Web Server Upgrade