Latest

-

Future Swim School

Leichardt swim school installs CHEMTROL® controller to improve water quality, meet health regulations and keep bathers safe

Client: Future Swim

Facility: Swim school

Equipment: CHEMTROL® PC110c Programmable Controller

Future Swim is a swim school in Leichhardt that caters for local children at the entry-level ‘learn to swim’ stage. It also has swim schools in three other locations across Sydney. Their experience with a basic, residential controller and manual testing/dosing led them to approach Chemtrol. The objective was to install a modern digital controller that provided an automated solution to maintain water quality and protect their users.

After assessing their setup and needs we recommended they install the PC110c Programmable Controller, a unit that features automatic maintenance of water chemistry, Free chlorine control (ppm) with pH, as well as TDS and ORP for sanitation backup. This unit also provides remote monitoring with full visibility and control.

We chatted to owner Andy Vu, for his experience and insights after installing the new unit.

What type of facility do you have and how many people use the facility?

We have a relatively small, single ‘learn to swim’ pool of 9m x 4m, with a volume of 40,000 litres. Depending on lessons the bather load can be anywhere from 500 – 700 swimmers per week.

We cap the number of classes and children in each class to ensure that we pay the right amount of attention to each child and their progression.

This works out to be a maximum of 6 babies (with parents), a maximum of 3 children per beginners class, and a maximum 4 for the older, more advanced kids.

What was your biggest challenge maintaining water quality?

Our previous equipment was a basic residential controller, which we combined with manual testing of the water and dosing. We found this unit to be too basic for our needs, as it did not measure chlorine levels – only ORP. Relying on our staff to conduct manual testing was also time consuming and we were also using a lot of chemicals due to the high bather load in a relatively small pool.

Our TDS was as high as 5000 sometimes, which is unacceptable – and as a public facility we have to meet state laws regarding chemical levels and the safety of our pool water. Support from the manufacturer of the controller also wasn’t great when we tried to get help or advice. They also had high staff turnover so we were dealing with a new person every time. I wanted a solution that was more accurate, automated and took the pressure off my staff.

“I wanted a solution that was more accurate, automated and took the pressure off my staff.”

How did you come across Chemtrol?

I was actually referred by a contact in the pool industry. They are responsible for the maintenance and servicing of a swimming pool in a hospital, and recommended a Chemtrol controller based on an installation there.

Why did you choose Chemtrol controller?

I researched the market thoroughly and spoke to a few other manufacturers, but decided to give Chemtrol an opportunity.

I liked the fact the controller is designed for a commercial environment, and comfortably handles everything for much bigger pools than ours. It also has all the necessary readings and data we required, including free chlorine, pH, ORP, TDS and Temperature – as well as remote monitoring capability. The controller and its components are all repairable and parts like the chlorine sensor are available to order. Our previous unit you basically had to replace if anything went wrong.

“I liked the fact the controller is designed for a commercial environment, and comfortably handles everything for much bigger pools than ours.”

What other features do you most appreciate about the Chemtrol unit?

I like the fact I can use and control it directly from my phone which is great. My staff have also found it easy to use after being trained.

What is your overall experience of Chemtrol and the installation process?

I have had a positive experience with the level of service. Kobby has always been there if we have questions or issues. He also took the time to train us how to use the unit, and has even Facetimed with us to resolve an issue or share advice. In this industry it’s hard to find a plumber who is willing or able to service our systems. It takes the pressure off us trying to solve an issue or try do the work.

CHEMTROL® PC110c Controller

The CHEMTROL® PC110c Controller is a programmable control system that offers complete chemical automation for pools and spas. This includes:

- Free Chlorine control (ppm)

- pH

- ORP

- TDS

- Temperature and heater control

- Water balance with Langelier Index

This model also incorporates our unique solid-state PPM SENSOR that generates easy-to-use, direct and reliable readings of Free Chlorine concentration in water.

Get in touch for advice on the best programmable controller for your swim school or commercial aquatic facility, that way we can provide a competitive pricing solution based on the functionality you need.

-

Sustainability: Cooling Towers

Sustainability and Cost Benefits of CHEMTROL® Controllers:

Cooling TowersSYDNEY, NSW – 03 Feb 2022

Installation of CHEMTROL® programmable controllers for cooling towers

Cooling towers by their very nature consume water as they perform their function of evaporative cooling. This is primarily via bleed, evaporation, makeup and drift losses.

For large facilities this can be one of the highest water-use areas, and account for up to 50% of the site’s water use.

” With this in mind we want to highlight how our range of smart automated water treatment systems can improve efficiency and help your facility be more sustainable and cost efficient to operate “

Sustainability benefits for cooling towers

The sustainability and efficiency benefits of using our controllers – in conjunction with an experienced water treatment service provider – include:

Water Savings

Our state of the art chemical dosing systems enables operators to run higher cycles of concentration without having a negative impact on the cooling tower system. Running higher cycles of concentration will save on bleed and make-up water.Energy Savings

Scale build up within a cooling tower system will affect the heat transfer capacity of the cooling towers/chillers. Controlling scale formation and dissolving any already formed substrate will improve the heat transfer capacity of the system, and therefore, reduce operating costs. A properly designed and sized chemical dosing and filtration system will improve system performance by allowing accurate chemical dosing to achieve desired parameters and removing suspended solids from the recirculating water. This helps keep cooling systems operating at maximum design efficiency.Longer Equipment Life

Maintaining clean tower water significantly reduces the potential for corrosion throughout the cooling system. Keeping the system surfaces clean allows the corrosion inhibitors to more effectively form the desired protective film on metal surfaces. State of the art chemical dosing and filtration systems also help prevent under-deposit corrosion.Improved Microbiological Control

Filtering bacteria and their food supply from the tower water significantly reduces the potential for microbiological growth and helps the biocide program work better.Reduced Maintenance

Unscheduled maintenance and downtime can be extremely costly. Using our controllers ensures that only clean water recirculates, which is not only sound preventive maintenance, but also reduces heat exchanger and tower cleaning costs.

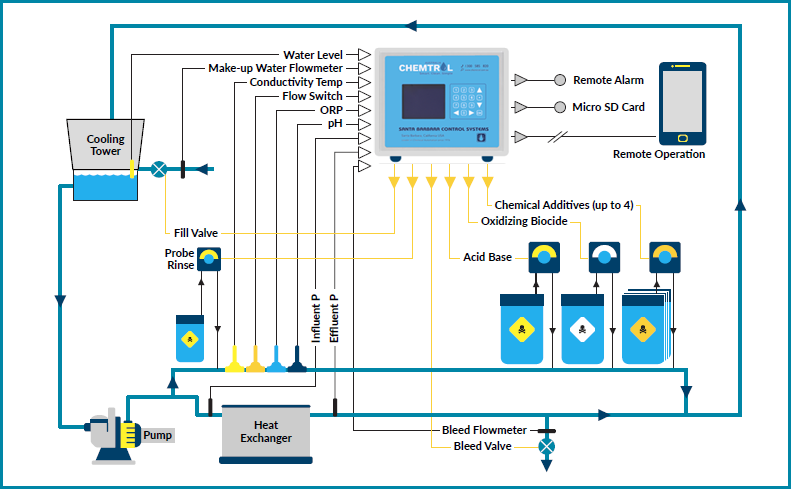

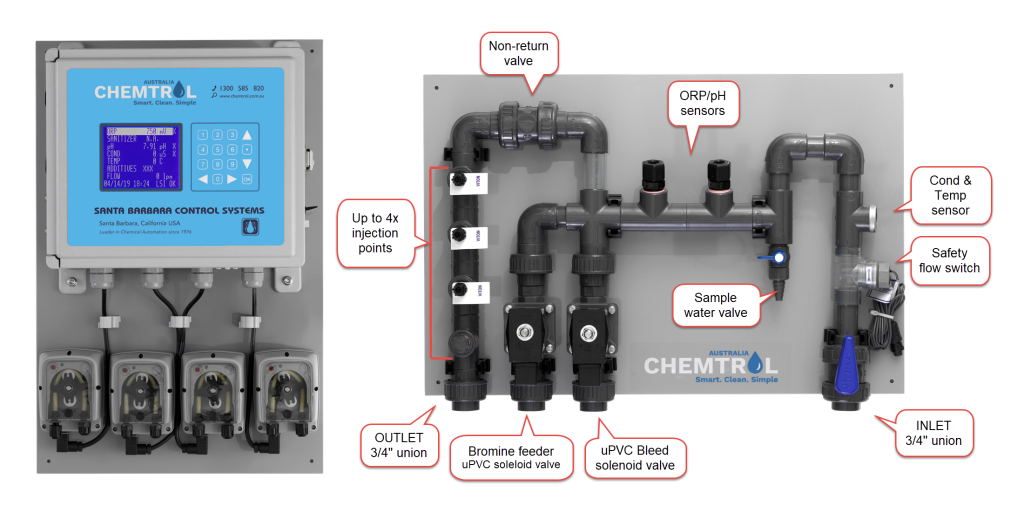

CHEMTROL® CT110 controller diagram installations

CHEMTROL® Cooling Tower Specific Controller

- CHEMTROL® CT110 controller is an easy-to-use but sophisticated programmable controller designed for control of conductivity (Total Dissolved Solids), ORP, pH, and programmable addition of chemical additives – such as inhibitors, biocides, dispersants, etc.

- Its makeup and bleed water-meter input is a standard feature, as is pH control with display of the Langelier Saturation Index (LSI).

- Optional chlorine or bromine level in part per million (ppm) measurement, as well as remote monitoring with our unique web-server communication offers true duplex operation with identical duplicate screens on both the controller and a computer, laptop, mobile App etc.

- Our cooling towers programmable controllers have the ability to be modified based on the type of monitoring and control you require. Customise your setup by adding or reducing components accordingly. That way we can provide a competitive pricing solution based on the functionality you actually need.

Why CHEMTROL® Controllers?

Highlights of our range of integrated controllers include:

- A chemical and energy saving program designed to reduce operating costs

- Web-based access for remote monitoring, full operation and control

- A generous, industry-leading 5-year electronics warranty on the controller

- For industrial facilities automated controllers give peace of mind that all mandatory public health obligations will be met with consistent disinfection under varying conditions

- Our products specifically designed for commercial and industrial applications.

CHEMTROL® and Sustainability

Santa Barbara Control Systems (SBCS), a California-based company is the manufacturer behind our range of Digital, Programmable & Integrated Controllers. With 40+ years of chemical automation, water chemistry research and expertise, CHEMTROL Australia is committed to providing solutions that help make our customers facilities and installations more sustainable. Our unique expertise also positions us to better understand our customers’ sustainability needs and gives us the ability to provide:

- Competitive features and pricing

- Advice on the most suitable product for your application

- Prompt technical support

For more information about our controllers please get in touch with us:

Phone: 1300 585 820Email: sales@chemtrol.com.au

Categories

- Yarra Ranges Council, Victoria

- Southern Swim School, Kirrawee NSW

- The new PC1500 range is now available

- Peristaltic metering pumps for pools and spas

- Booster backup for sanitiser + pH

- MidCoast Council and YMCA NSW

- Five-O-Five Apartments

- Future Swim School

- Sustainability: Cooling Towers

- Coughlan’s Swim Centre

- New features and functionality

- CHEMTROL wastewater controller helps ensure regulatory compliance

- URBNSURF Melbourne

- Lineage Logistics expands with CHEMTROL®

- Smart Web Server Upgrade

- PVDF Flow Fitting Products

- Building Control & Management Systems (BCMS)

- The Importance of Corrosion Monitoring

- CHEMTROL® Controllers Are 5G Compatible

- Total Cost of Ownership (TCO)

- North West Brewing Co

- Simplify the Complicated with the A1A Dosing Pump

- Kirby Swim School (WA)

- Dual Boiler Controller With Remote Monitoring Capability

- City of Sydney Aquatic Centres

- Mt. Wilga Private Hospital

- Newington College NSW

- Bradken Steel Foundry VIC

- Panthers Elite Sport Academy

- Sustainability: Swimming Pools and Spas

- Oaks Hyde Park Plaza

- New CT requirements NSW – 2018

- HydroFlow Water

- Cooling towers and Legionella

- Web Server Upgrade

- Emergent Cold