-

CHEMTROL wastewater controller helps ensure regulatory compliance

Client: HydroFlow Water

Facility: Poultry processing plant

Equipment: Chemtrol PC110xW

CHEMTROL controllers ensure water quality and regulatory compliance

Existing customer HydroFlow, a water treatment solutions provider with a national presence, facilitated the installation of our controller at a poultry processing plant.

Poultry processing plants have a range of potential environmental impacts that need to be mitigated, including the quality of the wastewater discharge they produce. South Australian Public Health (Wastewater) Regulations require the plant to meet stringent water quality parameters for the wastewater they generate prior to discharge from the facility.

We caught up with HydroFlow Equipment Specialist Matt Cotton, to find out more about the challenges of this project and more about his experience of the controller in this setting.

What type of facility is the controller installed at?

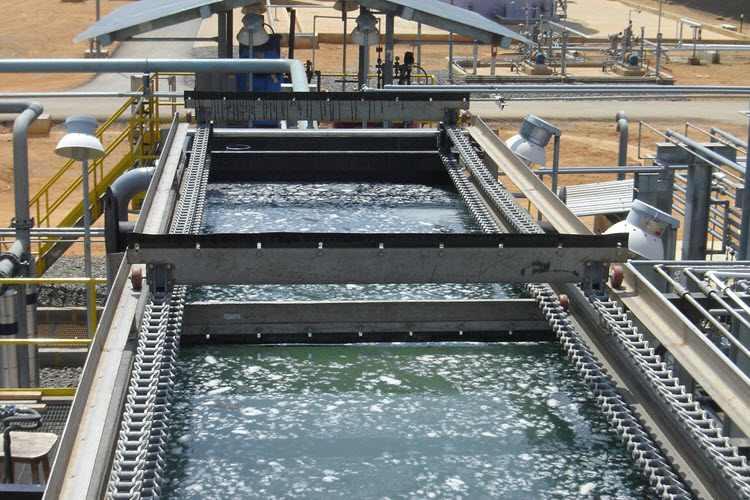

This particular installation is at a poultry processing plant in South Australia, which uses a Dissolved Air Flotation (DAF) system for wastewater treatment. This discharges around 30 litres/per sec (LPS) which goes into the SA Water wastewater system. It needs to meet the relevant regulations regarding wastewater and monitoring prior to discharge.

Tell us more about the regulatory requirements

There are a number of regulatory requirements around water quality and reporting.

The first is for South Australian Public Health Wastewater Regulations which stipulate certain parameters for the wastewater must be met, specifically the flow rate, pH, conductivity and turbidity.

The second requirement is that SA Water has 24/7 access to the plant wastewater discharge data, so they can monitor if the facility is meeting the relevant parameters. The client can get penalised if they exceed any of the parameters, and can even be prevented from discharging any wastewater if they are not compliant.

What specific function do the controllers do at your facility?

Essentially the controllers primary function is to ensure no bad wastewater goes into the public wastewater system. Key parameters it helps monitor and control at this site include:

- Turbidity, measured in Nephelometric Turbidity Units (NTU)

- Ph levels, i.e. the concentration of hydrogen ions in the water

- Conductivity, which is a measurement of dissolved minerals

- Flow, specifically the flow rate of wastewater discharged

Why did you choose Chemtrol controller?

The existing controller at this facility did not have a remote monitoring capability, so the plant could not meet the new regulations. SA Water basically needs online access to all the critical water chemistry data and parameters.

The Chemtrol controller’s remote access capability – via a PC or mobile app – means it was an obvious choice for this installation, ensuring regulatory compliance for our client.

” The Chemtrol controller’s remote access capability means it was an obvious choice for this installation, ensuring regulatory compliance for our client “

Did they help you overcome a specific problem?

The Chemtrol unit helped us solve a number of critical issues, namely ensuring our client:

- Could adhere to the regulations governing remote monitoring of their facility.

- Meets the relevant required monitoring of key parameters.

- Avoids being sanctioned and/or fined.

” Due to the precision and reliability of the controller the facility could also increase the rate of discharge from 30 LPS to 33 LPS “

Did you encounter any challenges on this project?

Yes, because of the amount of wastewater generated at this facility, the software on the flow meter had to be modified to measure LPS, as the standard unit was LPM.

Kobby and the Chemtrol team were patient and modified the software program so it could output this unit of measure. They also proved to be flexible and able to work with the challenges of this specific installation.

What features do you most appreciate about the controllers?

These controllers have some standout features including:

- Remote functionality, regarding monitoring and control

- Flexibility of the unit, enabling us to modify specific parameters

- Inline turbidity-meter (monitoring up to 10,000 NTU)

- SD card for easy upgrading and testing

What is your overall experience of Chemtrol and the installation process?

Hydro Flow has a long term relationship with Chemtrol, with multiple controllers installed at a range of facilities we manage across the country.

” The quality of the controller, pumps and probes is what gives us confidence in their accuracy and ongoing performance. The extended warranty period also puts our, and our clients minds at ease “

CHEMTROL® PC110xW controller

The CHEMTROL® PC110xW controller is a fully programmable controller designed for wastewater treatment applications, featuring:

- Remote control and monitoring capability

- Turbidity, pH, Conductivity, Temperature, and chlorine (ppm) control

- Inline turbidity-meter monitoring up to 10,000 NTU

- Two flowmeters input with totalizer | 4-20mA signal or pulse

- pH control with a choice of acid, co2 or base feed

- Chlorine sensor with direct reading in ppm or mg/l

- By-pass line assembly with safety flow switch and water sampling valve

- Langelier saturation index (LSI)

- On-board data logging with adjustable intervals

- Choice of 1, 2 or 3 point calibration

- Micro SD ports for easy program updates and data logging

Hydro Flow are leaders in the water management industry, providing expertise for a variety of systems including cooling towers, heated water systems, closed loop systems (chillers, boilers) corrosion prevention and wastewater treatment.

Get in touch for advice on the best controller for your needs. Our Municipal & Industrial Water selection chart can also help you decide what features you need and which CHEMTROL controller is right for your application.

Case Studies

- Southern Swim School, Kirrawee NSW

- MidCoast Council and YMCA NSW

- Five-O-Five Apartments

- Future Swim School

- Coughlan’s Swim Centre

- CHEMTROL wastewater controller helps ensure regulatory compliance

- URBNSURF Melbourne

- Lineage Logistics expands with CHEMTROL®

- North West Brewing Co

- Kirby Swim School (WA)

- City of Sydney Aquatic Centres

- Mt. Wilga Private Hospital

- Newington College NSW

- Bradken Steel Foundry VIC

- Panthers Elite Sport Academy

- Oaks Hyde Park Plaza

- HydroFlow Water

- Emergent Cold